can anyone offer any suggestions?

got a triac VMC and its starting to have z height issues. i do a lot of engraving and i set the z to zero, do a 5min job and when its finished its 0.6mm out.

ive done half a turn on the z gib screw but this hasnt made any difference, the screw is pretty tight.

all suggestions welcome.

so an update

with spindle off and z in the air. if i move x and y around manually z doesnt change.

if i start the spindle and dont touch anything else, the z height drops.

so maybe some interference? .

with spindle off and z in the air. if i move x and y around manually z doesnt change.

if i start the spindle and dont touch anything else, the z height drops.

so maybe some interference? .

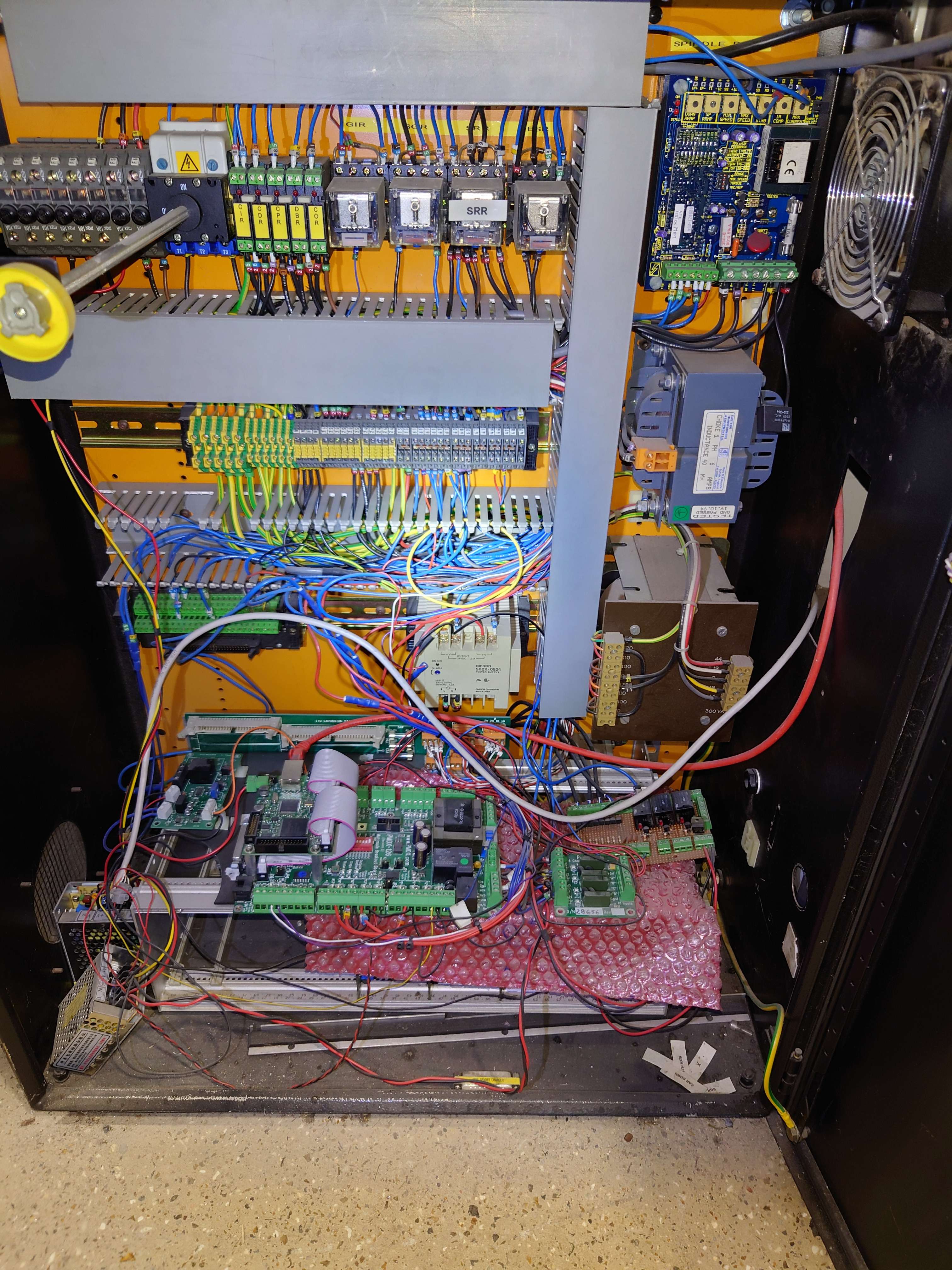

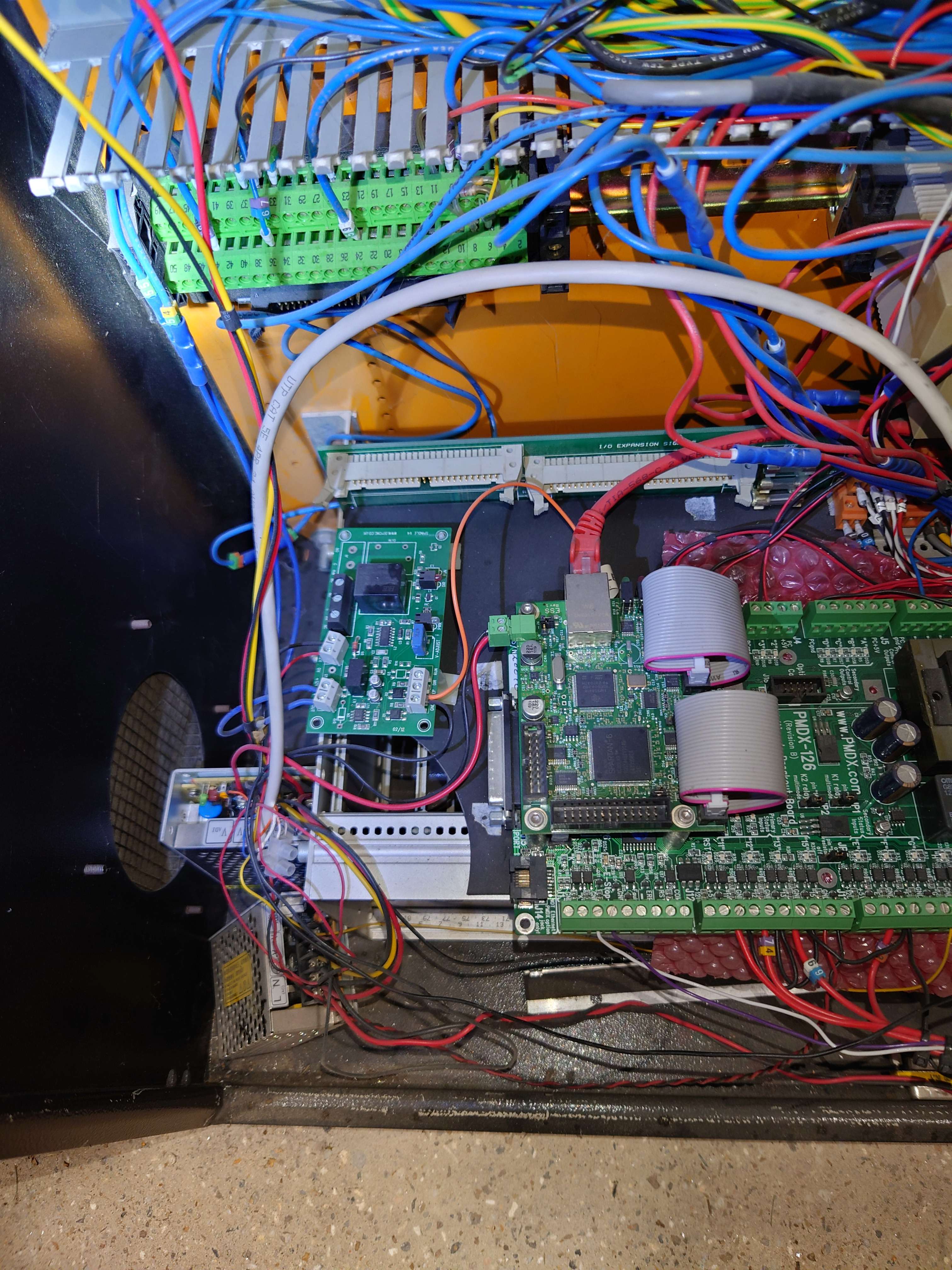

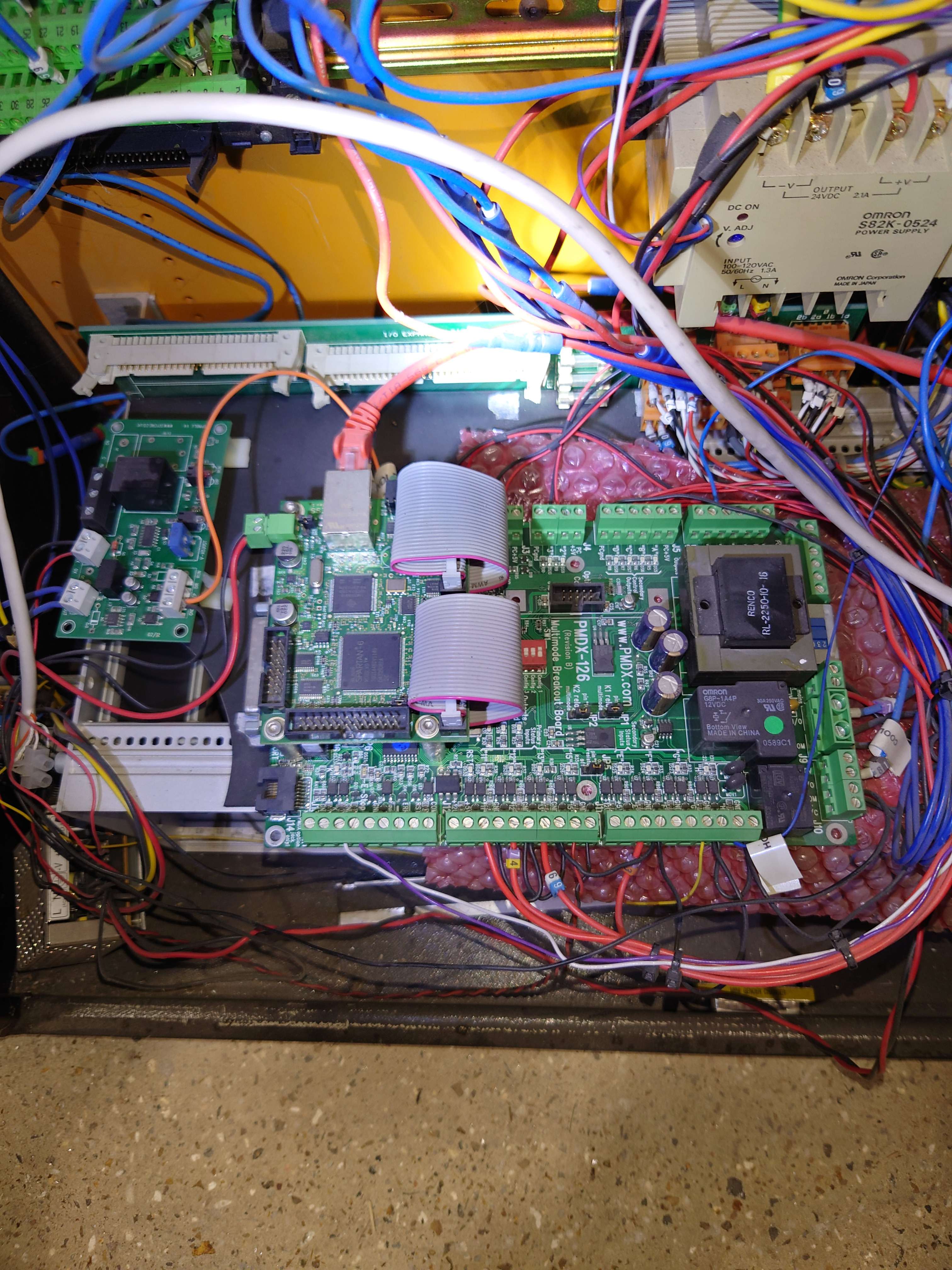

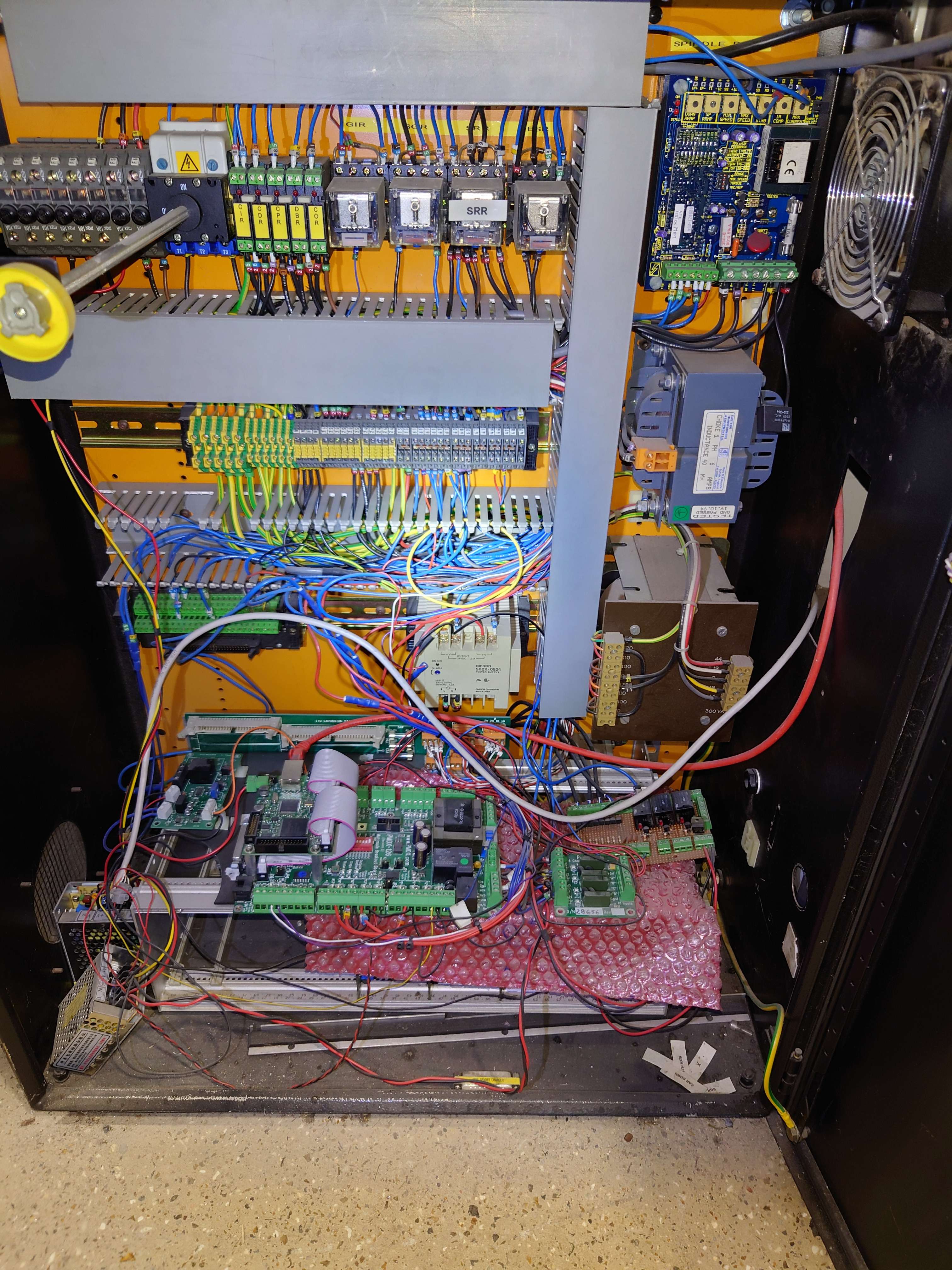

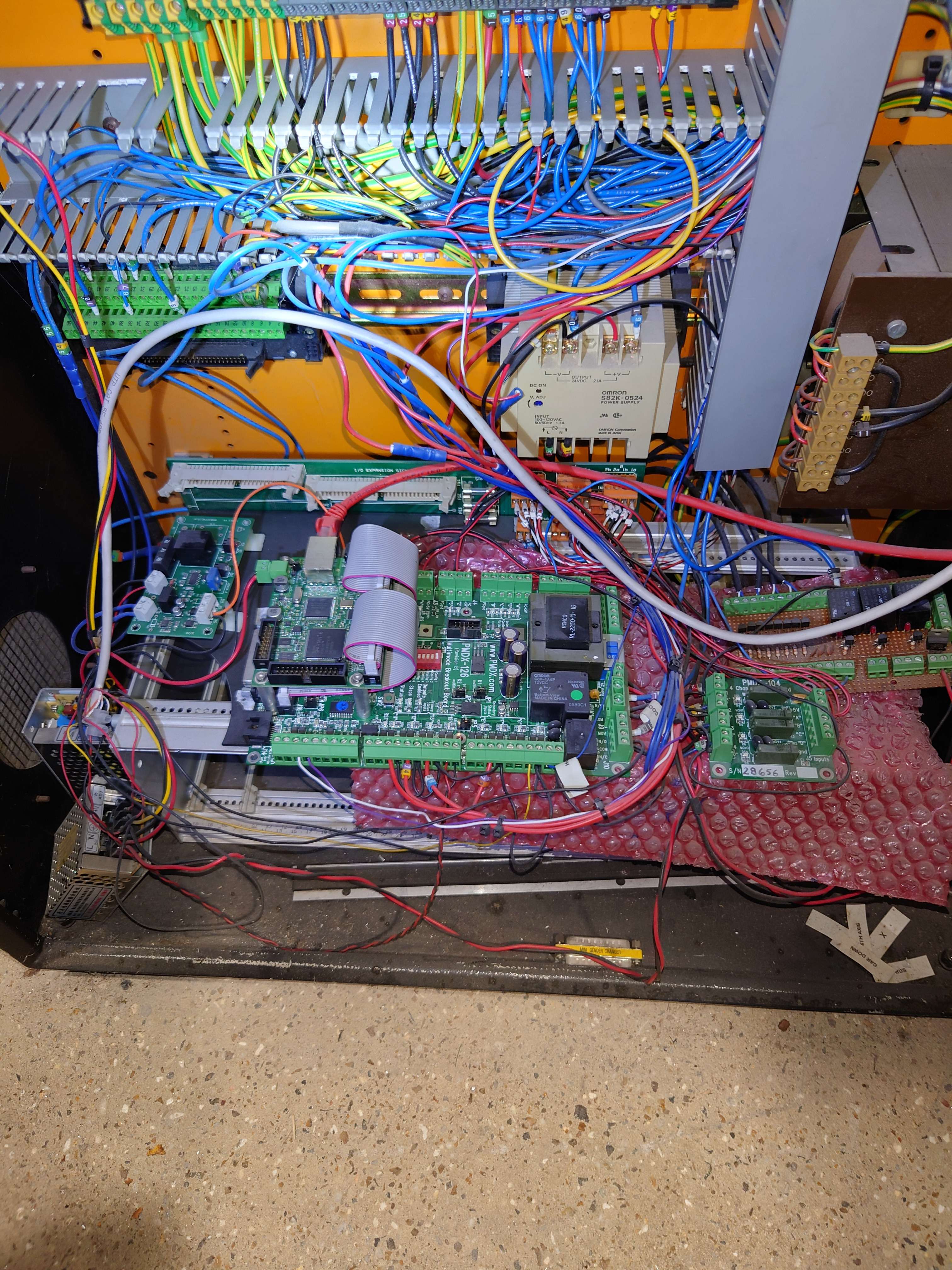

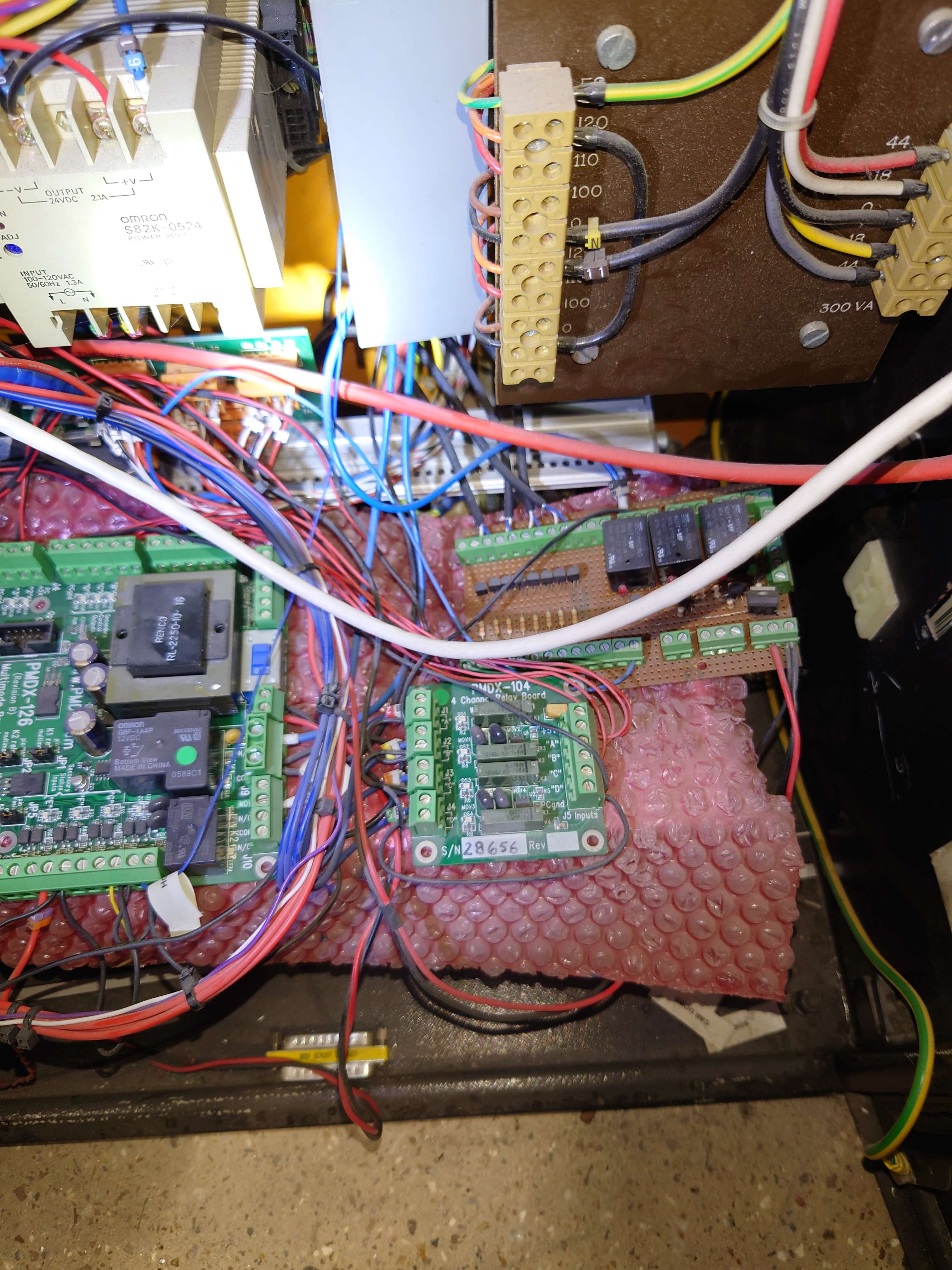

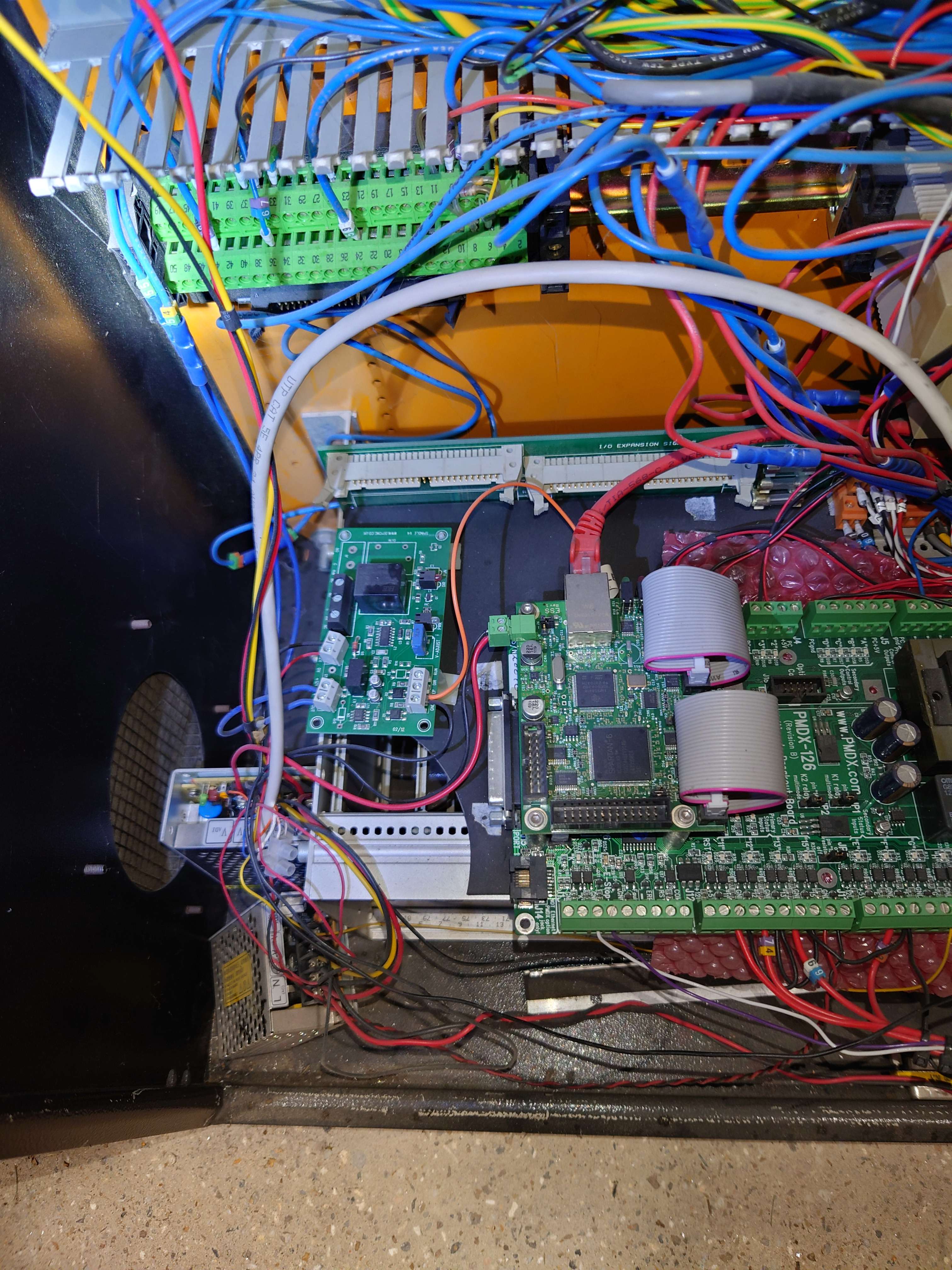

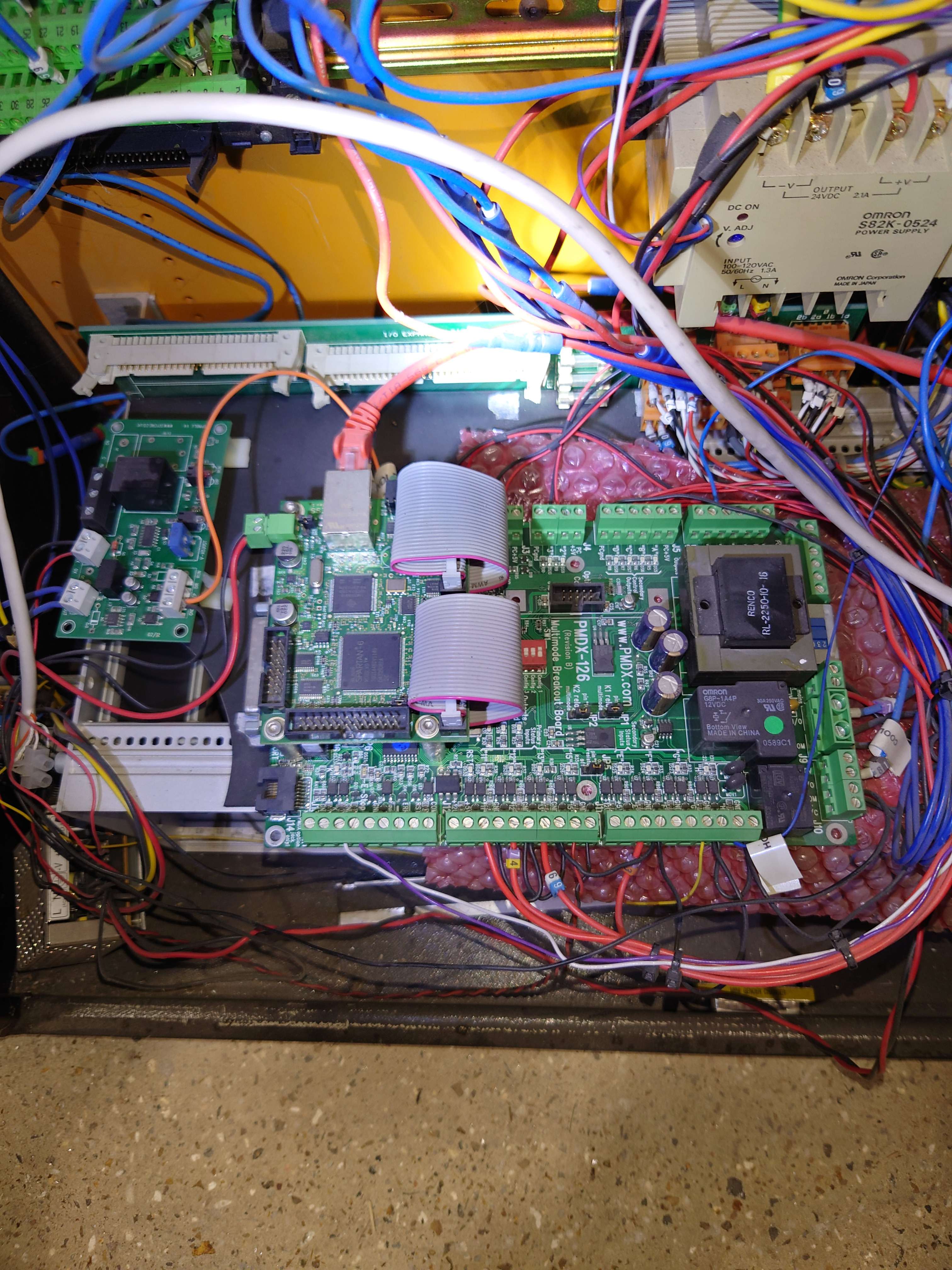

Can you post a picture of the inside of the electrical cabinet. I presume its a rack mounted control & drive fitted.

video

https://youtu.be/stbWpra7O_4

so you can hear the z stepper moving the z axis, the z isnt just dropping down slowly on its own.

ive owned the machine for around 10 years and whilst ive had many problems, ive not had this issue before.

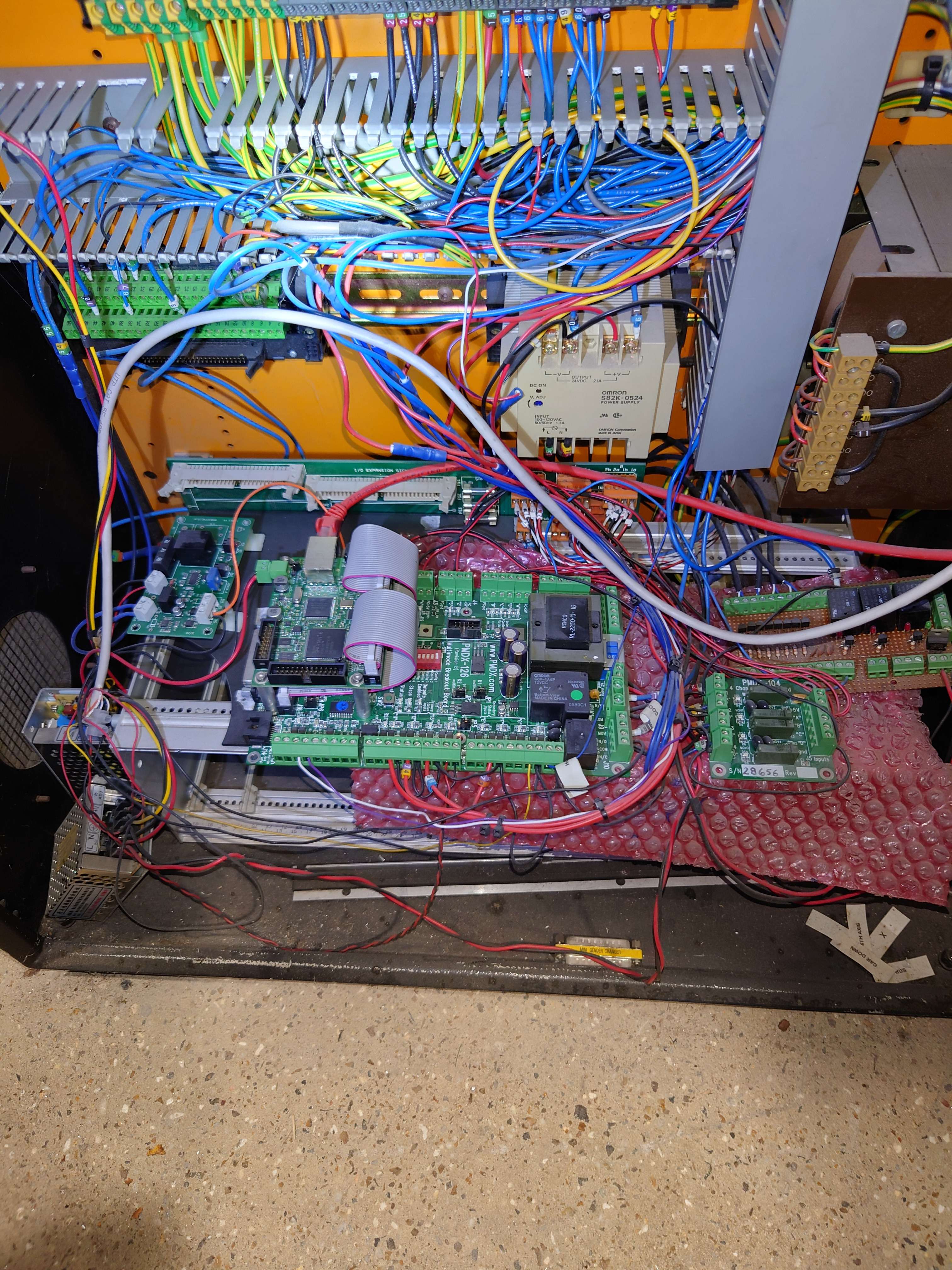

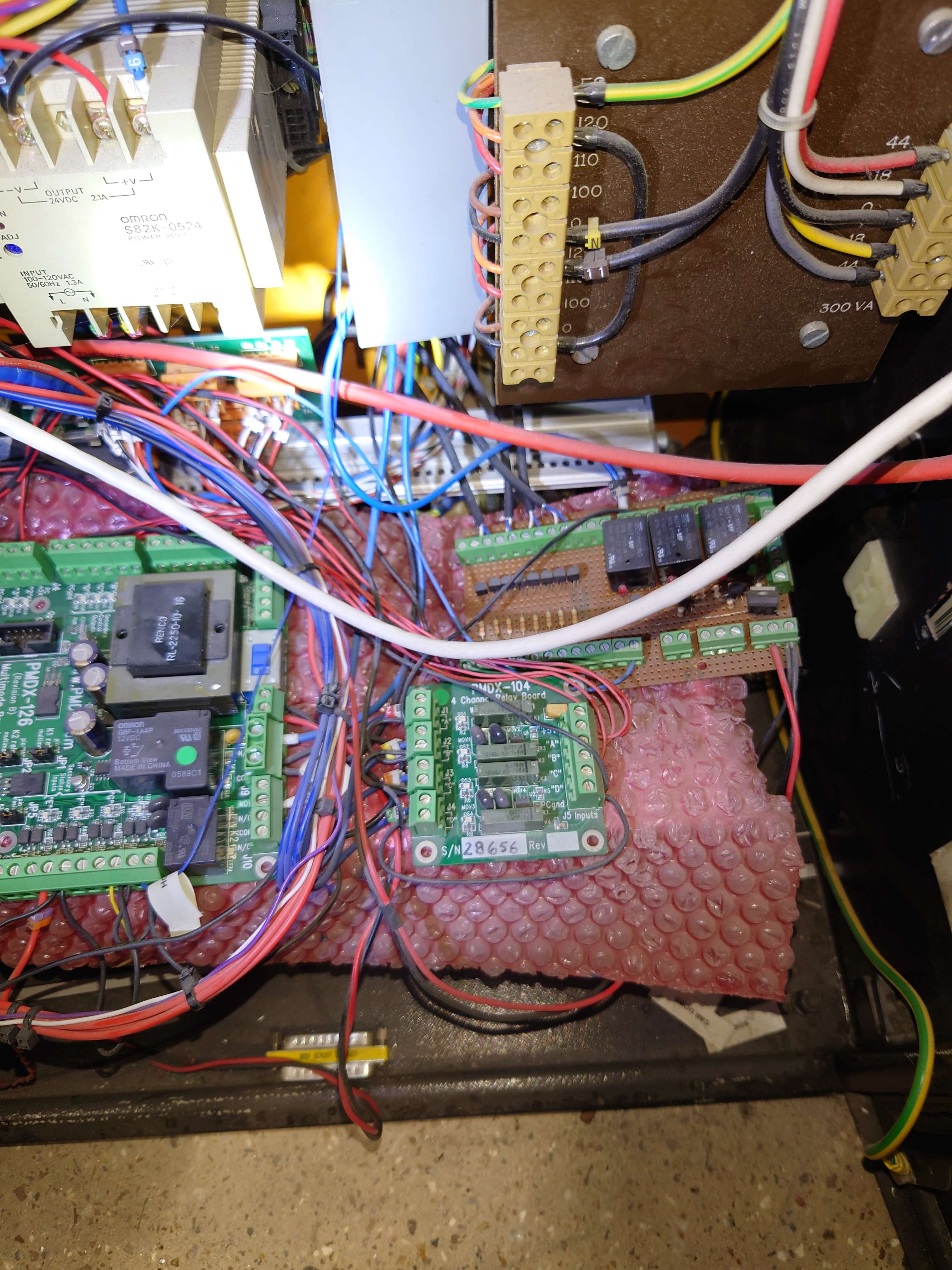

its not pretty inside sadly -

https://youtu.be/stbWpra7O_4

so you can hear the z stepper moving the z axis, the z isnt just dropping down slowly on its own.

ive owned the machine for around 10 years and whilst ive had many problems, ive not had this issue before.

its not pretty inside sadly -

another small update, when i change the spindle speed that seems to make the z also move.

but the z also moves without a change in rpm

but the z also moves without a change in rpm

I presumed you still had the original control fitted.

I would look at keeping the axis drive signals as far away form the spindle drive & spindle motor wires as possible.

I would look at keeping the axis drive signals as far away form the spindle drive & spindle motor wires as possible.

ive owned the machine for 10 years and this issue has only jsut started happening.

so there is clearly a new fault somewhere, i just dont know how to find it

so there is clearly a new fault somewhere, i just dont know how to find it

heres an interesting development.

so when the z is at its height it would be machining at i get this z movement issue. if i lower the z right down to near the table, in a position it wouldn't be machining at i dont get the z issue.

so am now wondering if its some kind of cable issue. about a year ago i did have a cable break on the inside on the atc, the years of movements must have broken the cable.

so when the z is at its height it would be machining at i get this z movement issue. if i lower the z right down to near the table, in a position it wouldn't be machining at i dont get the z issue.

so am now wondering if its some kind of cable issue. about a year ago i did have a cable break on the inside on the atc, the years of movements must have broken the cable.

i appear to be finding more issues than solutions at the moment!!

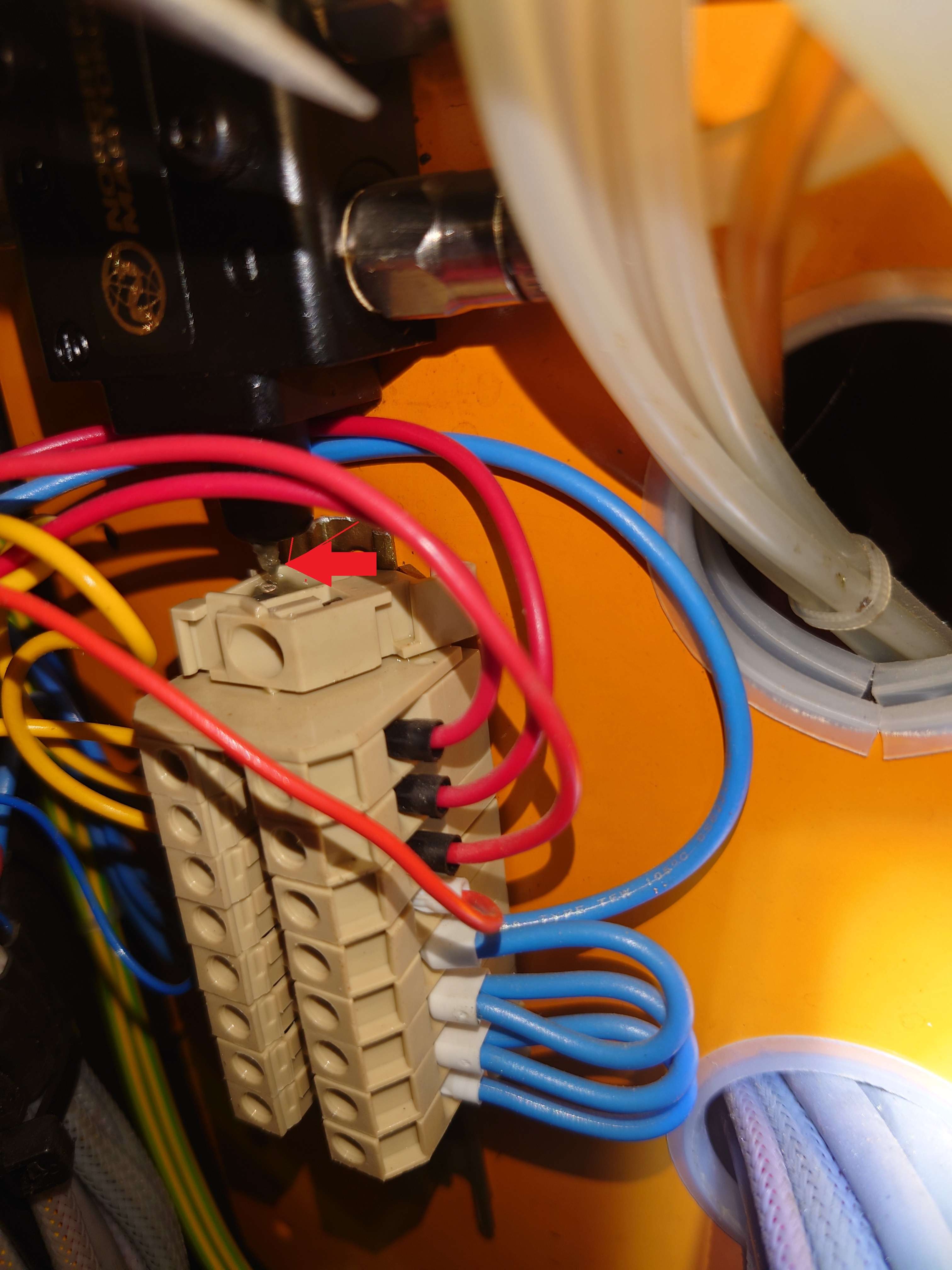

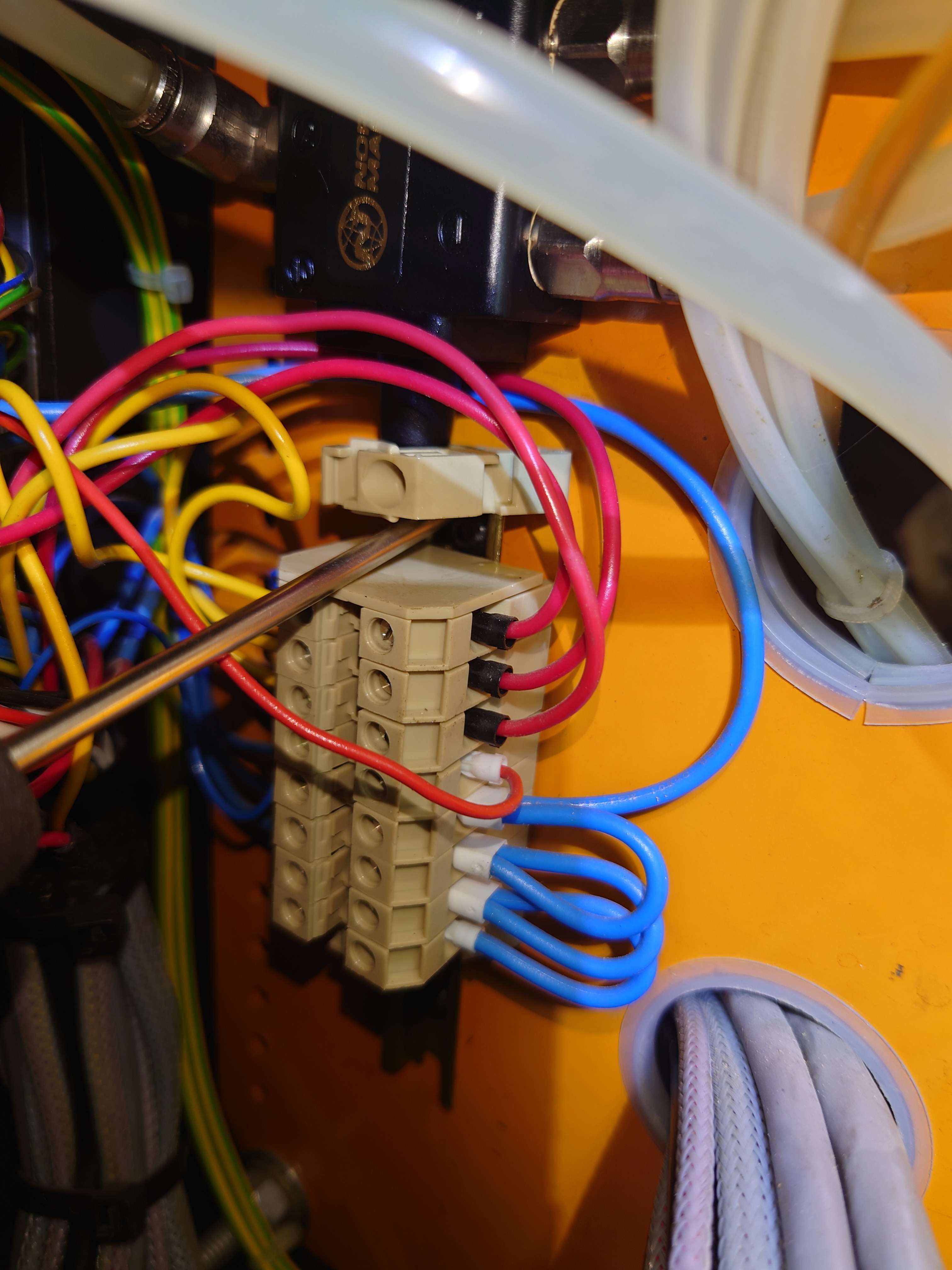

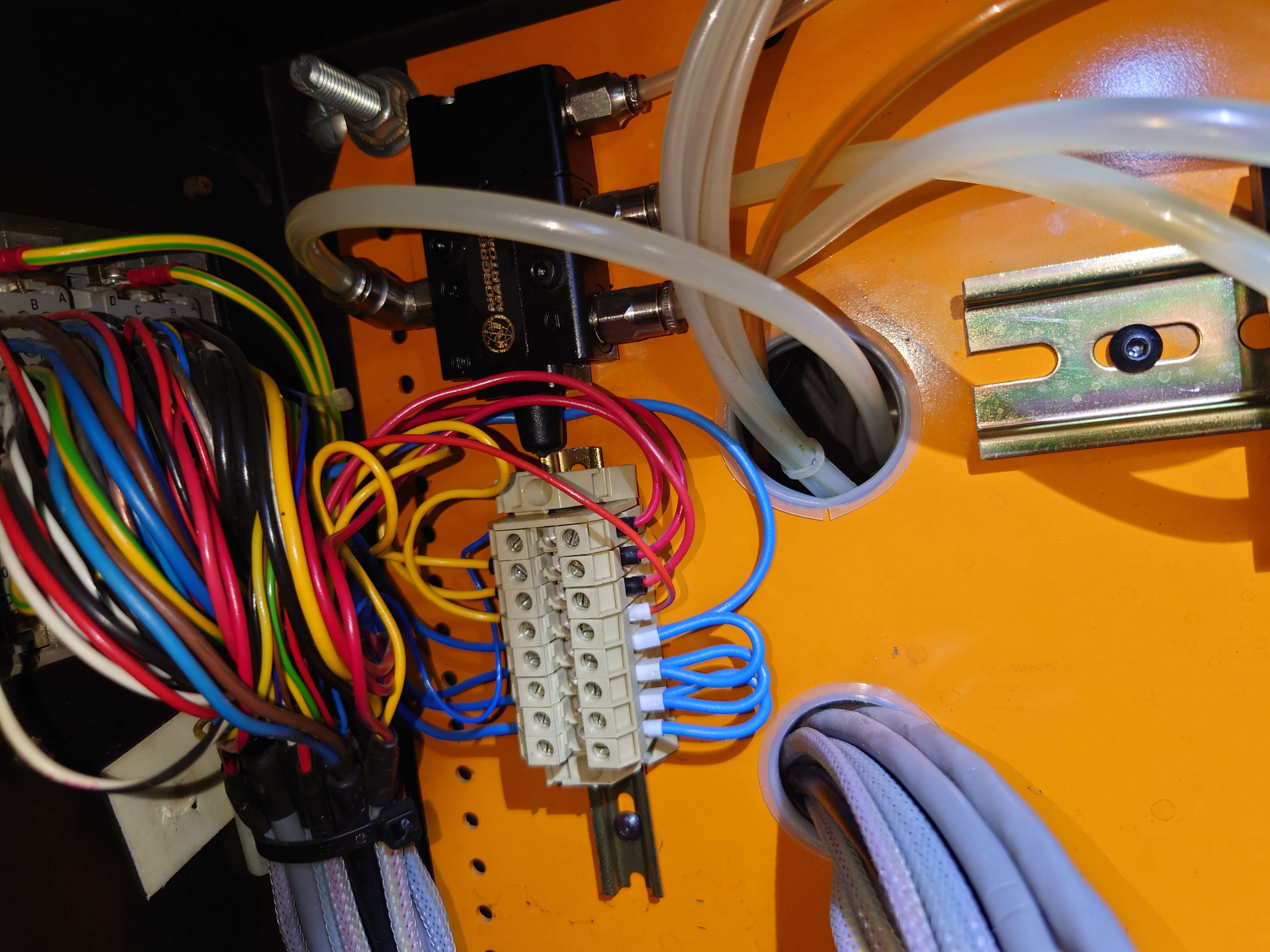

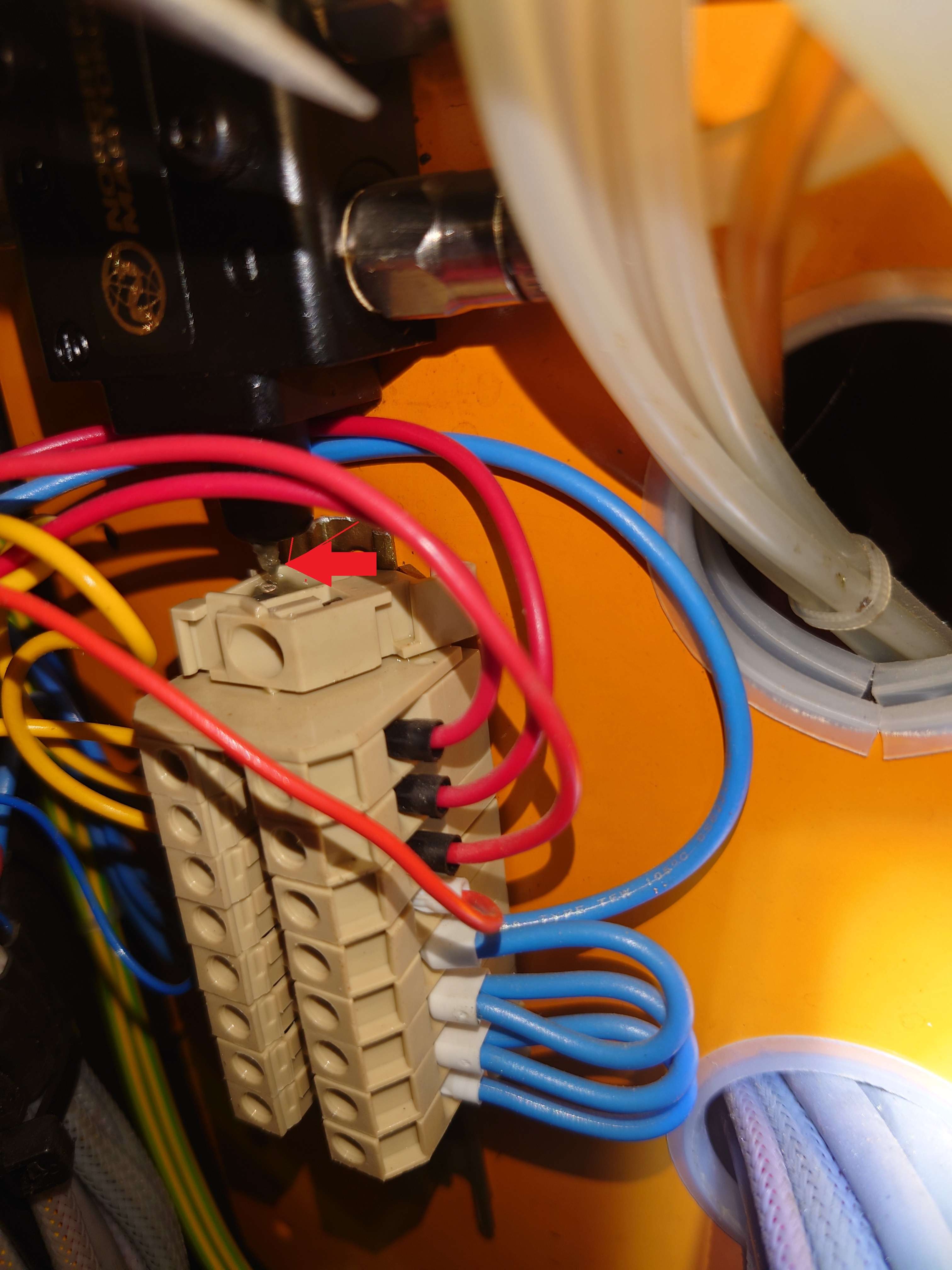

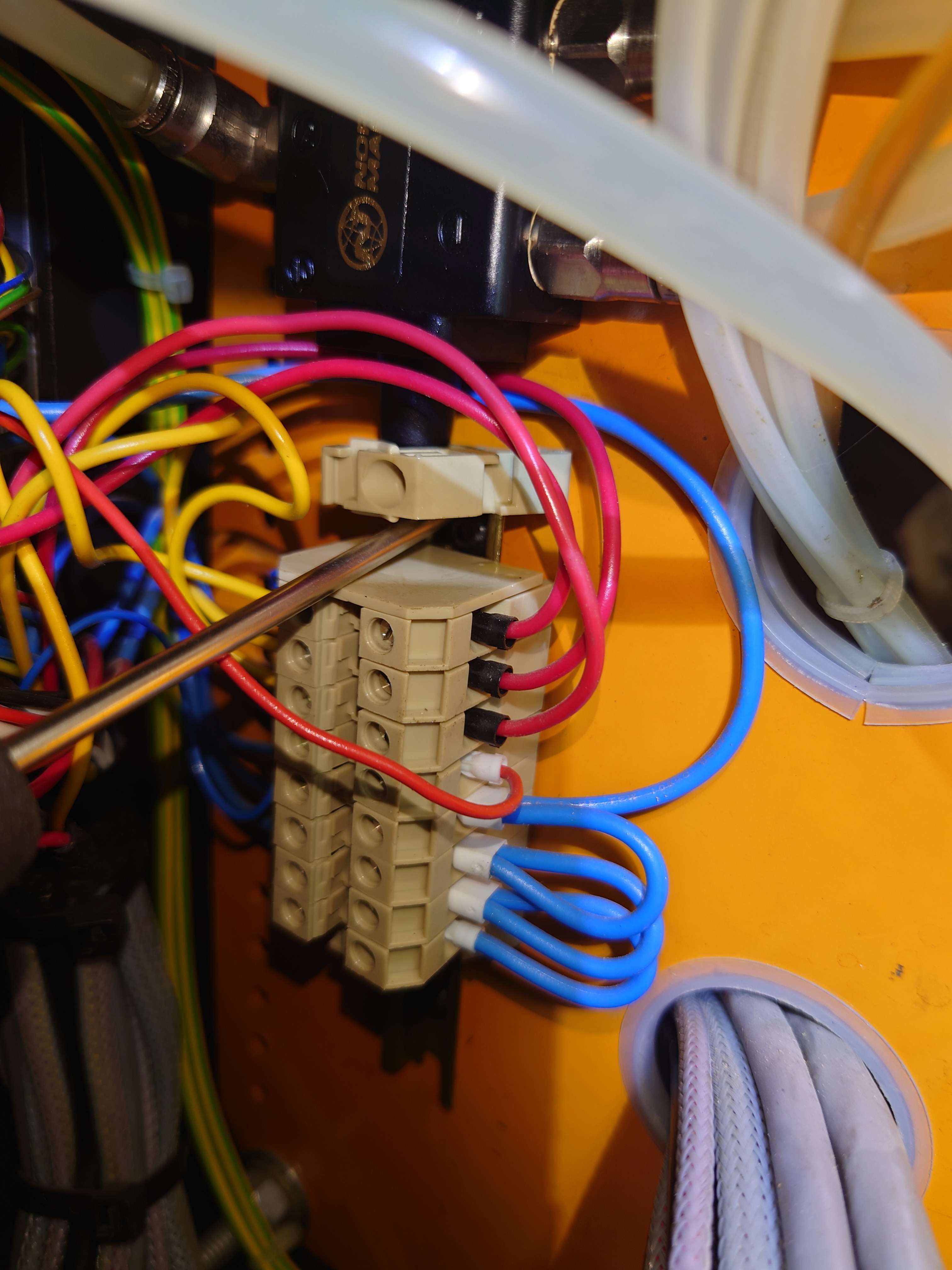

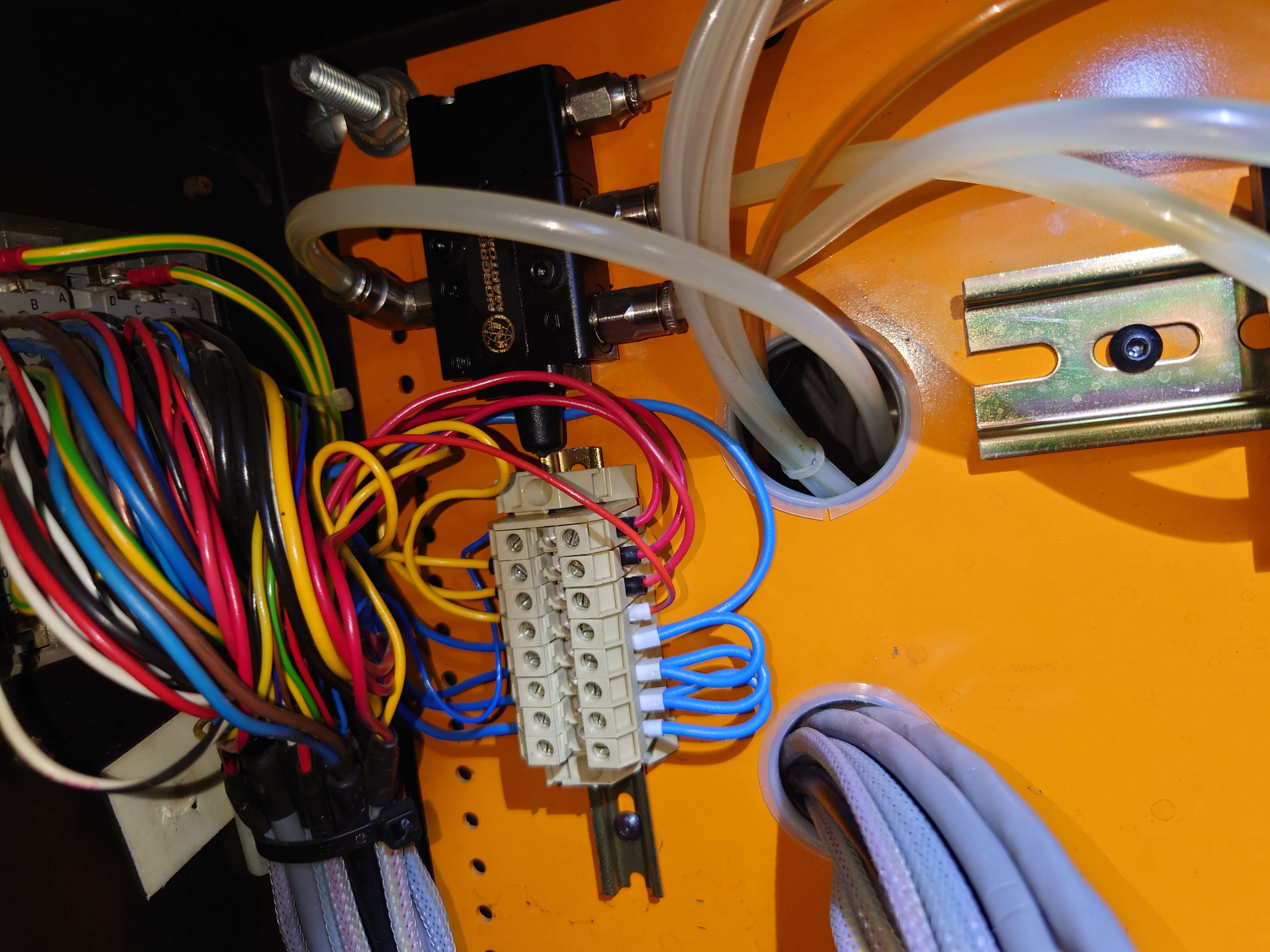

just opened the black box at the back of the machine and noticed the below.

goo coming from the black hose connector block and then the electrical block below is wet. its gone all the way to the bottom connector.

just opened the black box at the back of the machine and noticed the below.

goo coming from the black hose connector block and then the electrical block below is wet. its gone all the way to the bottom connector.