first off hi, signed up a little while ago when i got my 280 vs but all the help i needed was right here so didnt need to ask!

but now i do, the tachometer is totaly kaput, seems to be getting power but nothing at all lighting up. if there is a handy schematic available for the 280vs that would be very handy indeed, every single wire is black! nightmare to try and trace.

failing that i have found this - https://cgi.ebay.co.uk/ws/eBayISAPI.dll? ... :IT&ih=016 i asked the seller for a data sheet and was sent this link - https://www.e3b6a5y.com/365/WiringDiagra ... fTACHO.PDF

now will the pickup in the headstock provide the signal required to run this display on the square wave setting? or would it require a bit more jiggery pokery than just pluging it straight in.

any help would be much appreciated

chris

Chris,

Which version of the 280VS do you have?

Is it the mechanical version (handwheel below the headstock to adjust speed), or the electrical version with pendant control box mounted over the headstock?

Denford never had a schematic for the circuit boards (that I have been able to find anyway) - I believe they were designed and made by sub-suppliers.

I know of 2 variants of the circuit board in the pendant control (there may be more). One (the earlier design, I think) used separate transistors and resistors , whilst the other uses a Darlington array and resistor network components. They both basically work the same way.

I have a copy of the wiring diagram for the 280VS electric version, and I drew up a tacho circuit board schematic to work out was was missing and repair mine.

Once you have confirmed the model that you have, I will see if I can find them.

Andy

(edited to add details)

Which version of the 280VS do you have?

Is it the mechanical version (handwheel below the headstock to adjust speed), or the electrical version with pendant control box mounted over the headstock?

Denford never had a schematic for the circuit boards (that I have been able to find anyway) - I believe they were designed and made by sub-suppliers.

I know of 2 variants of the circuit board in the pendant control (there may be more). One (the earlier design, I think) used separate transistors and resistors , whilst the other uses a Darlington array and resistor network components. They both basically work the same way.

I have a copy of the wiring diagram for the 280VS electric version, and I drew up a tacho circuit board schematic to work out was was missing and repair mine.

Once you have confirmed the model that you have, I will see if I can find them.

Andy

(edited to add details)

Last edited by Andy B on Wed 21 Jan , 2009 16:33 pm, edited 1 time in total.

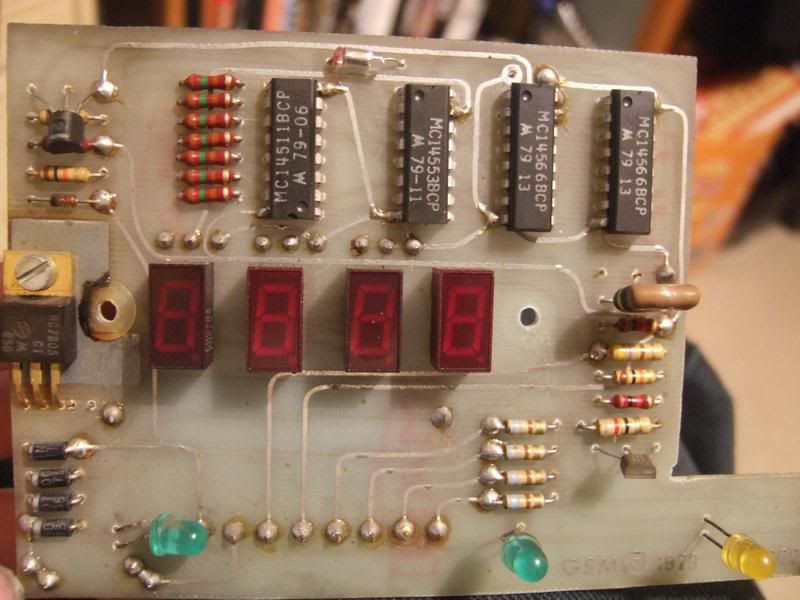

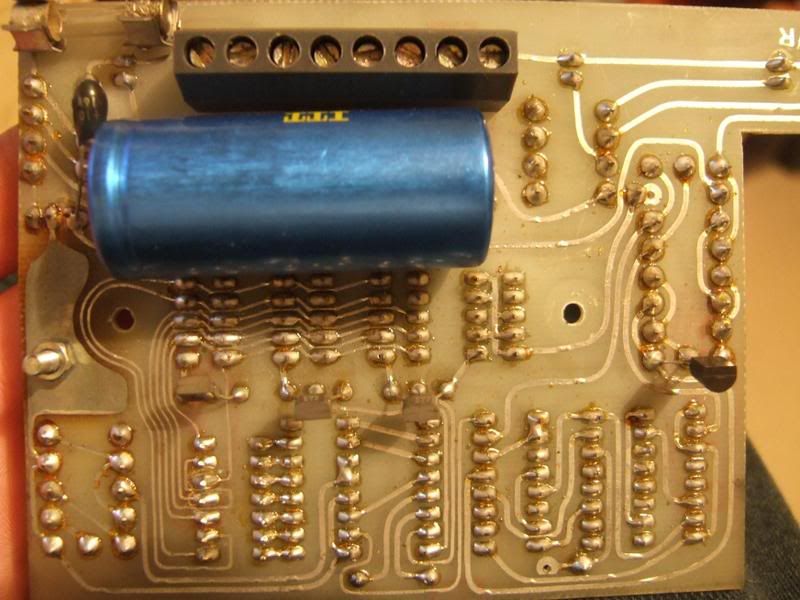

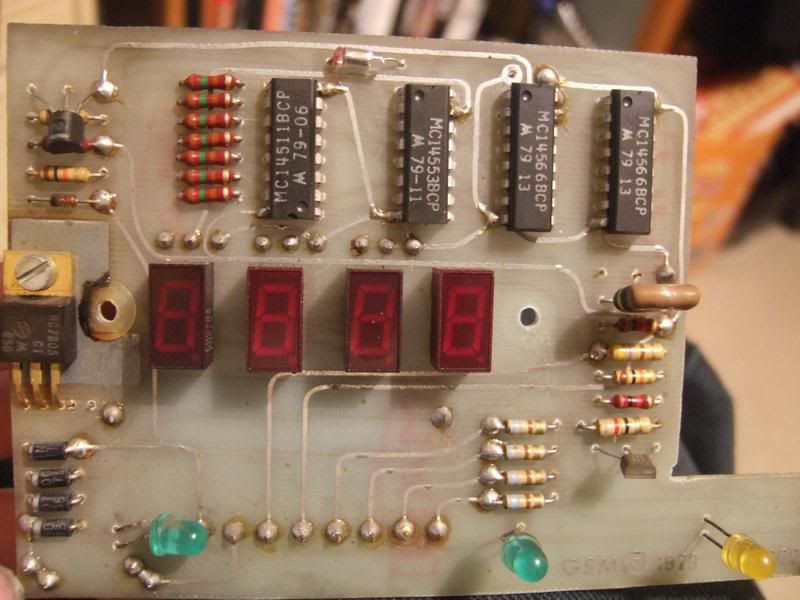

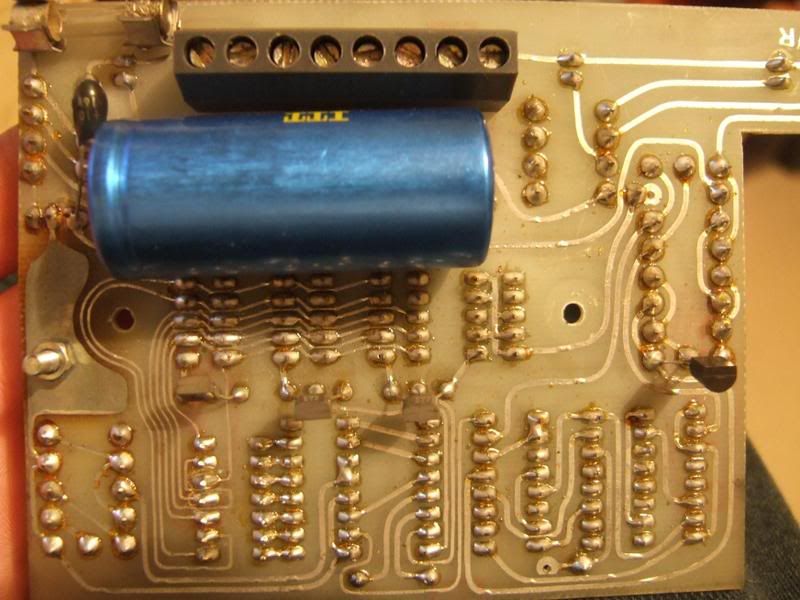

A couple of pictures to show the tacho circuit board variants to be found in the pendant controls.

The IC's are all readily available, but I have not managed to find a source for the numeric LED displays (one of mine has one bar that does not light up, but as it is the last digit and this always shows '0', it isn't really a problem).

Chris - are you getting a voltage reading on the output of the regulator?

Andy

The IC's are all readily available, but I have not managed to find a source for the numeric LED displays (one of mine has one bar that does not light up, but as it is the last digit and this always shows '0', it isn't really a problem).

Chris - are you getting a voltage reading on the output of the regulator?

Andy

Attachments:

i have the electrical version, think its an early one going by your pictures

here is mine

and yes i have checked the fuse

yes i am getting an output from the regulator, one thing though. when the machine has power should the display read 0000? or just nothing at all untill the chuck starts turning?

thought the sensor was at fault as i assumed it was a hall efect sensor and it had no resistance reading (open line) but upon taking it out it turns out to be a NAMUR sensor, didnt even know they existed till a few days ago

i have found a replacement sensor in the RS but would rather know it was the sensor at fault before i fork out £20 for nothing

trying to find out how to test such a device but no joy so far.

in the mean time i may have to rig up some contraption out of an old distributor and a tacho from a mini to set the speed

any help greatly appreciated

here is mine

and yes i have checked the fuse

yes i am getting an output from the regulator, one thing though. when the machine has power should the display read 0000? or just nothing at all untill the chuck starts turning?

thought the sensor was at fault as i assumed it was a hall efect sensor and it had no resistance reading (open line) but upon taking it out it turns out to be a NAMUR sensor, didnt even know they existed till a few days ago

i have found a replacement sensor in the RS but would rather know it was the sensor at fault before i fork out £20 for nothing

trying to find out how to test such a device but no joy so far.

in the mean time i may have to rig up some contraption out of an old distributor and a tacho from a mini to set the speed

any help greatly appreciated

Chris,

Yes, the display should light show '0000' as soon as you apply power to the lathe - so I don't think the sensor is faulty necessarily.

Attached is the schematic I drew up for the later type of circuit board.

As mentioned previously, yours should be essentially the same except for having transistors in place of the ULN2003N Darlington arrays and separate resistors in place of the resistor arrays (IR1 & IR2).

I compiled it from tracing the circuit board tracks - a tedious task but got me the answer as to what components I was missing!

It took me a while to work out the circuit logic (normally off, with a pulsed 'on' period) - you may well have a far better electrical knowledge than me, but if you want the benefit of my limited findings please ask.

Hope this helps

Andy

Yes, the display should light show '0000' as soon as you apply power to the lathe - so I don't think the sensor is faulty necessarily.

Attached is the schematic I drew up for the later type of circuit board.

As mentioned previously, yours should be essentially the same except for having transistors in place of the ULN2003N Darlington arrays and separate resistors in place of the resistor arrays (IR1 & IR2).

I compiled it from tracing the circuit board tracks - a tedious task but got me the answer as to what components I was missing!

It took me a while to work out the circuit logic (normally off, with a pulsed 'on' period) - you may well have a far better electrical knowledge than me, but if you want the benefit of my limited findings please ask.

Hope this helps

Andy

Attachments:

you sir are a legend

not a master of electronics by any means! i did an HNC about 8 years ago and failed on writen communication which was a core unit fail electronics for sentence construction. (never of guesed with my spelling

fail electronics for sentence construction. (never of guesed with my spelling  )

)

anyway, after a quick looka at your very handy schematic it looks like the 4th display is wire to show 0 constantly? is that right? if it is then there must be a power problem somewere or that display would light up no matter what may be wrong with the I.C's.

maby its an earth fault shall do some checking at the weekend when im at the workshop armed with your diagram, was sure there was power though

shall do some checking at the weekend when im at the workshop armed with your diagram, was sure there was power though

although your diagram dosnt show the LED's, and they do indeed light up on command. tempted to go there now but im just in from work and its 20 miles away

any help describing the operation is welcome

not a master of electronics by any means! i did an HNC about 8 years ago and failed on writen communication which was a core unit

anyway, after a quick looka at your very handy schematic it looks like the 4th display is wire to show 0 constantly? is that right? if it is then there must be a power problem somewere or that display would light up no matter what may be wrong with the I.C's.

maby its an earth fault

although your diagram dosnt show the LED's, and they do indeed light up on command. tempted to go there now but im just in from work and its 20 miles away

any help describing the operation is welcome

I've uploaded the datasheet for the seven seg display here:

viewtopic.php?t=1940

Its hard to tell what the 4th display is hardwired to display without the pin numbers, but at least the datasheet will help you work it out...

viewtopic.php?t=1940

Its hard to tell what the 4th display is hardwired to display without the pin numbers, but at least the datasheet will help you work it out...

Chris,

Yes, the 4th (right hand) digit should always display '0'. But.... see note later.

I don't have all my info to hand, but if I remember right the 4 LEDs (2 green for speed change and 2 yellow for spindle direction) work off the 10.5V AC input - they do not use the rectified / voltage controlled supply that feeds the transistors, IC's, etc, so are not a test of that part of the circuit board.

So I'm sure it is a problem on the board somewhere.

Now, as I mentioned in my last post, the digit displays (all 4 of them) are 'pulse' lit - which is done by switching the 'ground' of the displays from V(in) to 0. So the time base generator IC's and the ground switching transistor must be working to get even the 4th digit to display '0'.

If you definitely have an output from the voltage regulator, I'm not sure how you would test the switching circuit without a scope -other than replacing components one at a time (I'm fortunate to have a very good local electronics shop that stocks transistors, etc - so its less than £5 to replace the timer IC's and the transistors).

Andy

Yes, the 4th (right hand) digit should always display '0'. But.... see note later.

I don't have all my info to hand, but if I remember right the 4 LEDs (2 green for speed change and 2 yellow for spindle direction) work off the 10.5V AC input - they do not use the rectified / voltage controlled supply that feeds the transistors, IC's, etc, so are not a test of that part of the circuit board.

So I'm sure it is a problem on the board somewhere.

Now, as I mentioned in my last post, the digit displays (all 4 of them) are 'pulse' lit - which is done by switching the 'ground' of the displays from V(in) to 0. So the time base generator IC's and the ground switching transistor must be working to get even the 4th digit to display '0'.

If you definitely have an output from the voltage regulator, I'm not sure how you would test the switching circuit without a scope -other than replacing components one at a time (I'm fortunate to have a very good local electronics shop that stocks transistors, etc - so its less than £5 to replace the timer IC's and the transistors).

Andy

Just compared the circuit board pictures again, and Chris' appears to be a 3rd variant, having a bank of resistors alongside the MC14511 LED driver IC.

So I'm guessing that in my 'type 1' picture, the 3 resistors on above the digit displays must be on the ground side (they look to be connected to the rail that goes to Vss on the time base generator IC's).

Chris - what is the black colour around the hole next to the voltage regulator? Has it been getting a bit warm?

And finally, I just checked the wiring diagram (Drg no SK601A) and confirmed that the 4 LEDs are run off the AC input.

Andy

So I'm guessing that in my 'type 1' picture, the 3 resistors on above the digit displays must be on the ground side (they look to be connected to the rail that goes to Vss on the time base generator IC's).

Chris - what is the black colour around the hole next to the voltage regulator? Has it been getting a bit warm?

And finally, I just checked the wiring diagram (Drg no SK601A) and confirmed that the 4 LEDs are run off the AC input.

Andy

black bit does look a bit suspect, its the plastic insulating washer. thought it was just muck, this lathe has been messed about with quite a bit! someones been in there before me but with obviously no luck

will give it a good going over tomorrow, but that does look a bit like a burnt out regulator

also just noticed a project section here, will post what i have been up to and the other problems with this machine

also just confirm in getting this right, looking from the front of the regulator as in the first photo.

10v in left, earth middle, 5v out right. if it is i can get another from maplin for 63p

will give it a good going over tomorrow, but that does look a bit like a burnt out regulator

also just noticed a project section here, will post what i have been up to and the other problems with this machine

also just confirm in getting this right, looking from the front of the regulator as in the first photo.

10v in left, earth middle, 5v out right. if it is i can get another from maplin for 63p

well i am officially a plum  did all my testing before the lathe was wired up so the readings were a bit inaccurate to say the least.

did all my testing before the lathe was wired up so the readings were a bit inaccurate to say the least.

tested the regulator again and it was dead, so went and got another, exact same spec

BUT it nearly cooked itself the same as the old one did, something is wrong elsewere

when the machine is powered up the 4 digits flash then the first 3 go out very fast and the 4th fades a bit slower, the power is being sapped somewere and its overloading the regulator.

didnt take my bloody multi meter with me so couldnt do any tests with it hooked up to the lathe

took the circuit home and hooked a battery pack to the regulator, same thing happened but could measure the volt drop and it was pretty rapid!

one other thing i wanted to check but couldnt, AC voltage was 10.4v when i first measured it but dc was at 14.5 how can a rectifier boost voltage? dosnt it usualy reduce it a bit?

how can a rectifier boost voltage? dosnt it usualy reduce it a bit?

anyone got a spare tachometer circuit they want to sell

tested the regulator again and it was dead, so went and got another, exact same spec

BUT it nearly cooked itself the same as the old one did, something is wrong elsewere

when the machine is powered up the 4 digits flash then the first 3 go out very fast and the 4th fades a bit slower, the power is being sapped somewere and its overloading the regulator.

didnt take my bloody multi meter with me so couldnt do any tests with it hooked up to the lathe

took the circuit home and hooked a battery pack to the regulator, same thing happened but could measure the volt drop and it was pretty rapid!

one other thing i wanted to check but couldnt, AC voltage was 10.4v when i first measured it but dc was at 14.5

anyone got a spare tachometer circuit they want to sell