Page 1 of 1

8 station ATC vs 6 station ATC - differences?

Posted: Fri 10 Jul , 2015 17:12 pm

by andy_con

in order to get an 8 station atc in a triac did denford position the tool changer differently on the 8 version so it fits?

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Fri 10 Jul , 2015 23:21 pm

by Lone_Ranger

andy_con wrote:in order to get an 8 station atc in a triac did denford position the tool changer differently on the 8 version so it fits?

I think it was just the tool holder sizes that determined the number of pots, 8 station were BT30 and the 6 station were BT35

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Sat 11 Jul , 2015 8:45 am

by Martin

The machines we make now use the same tools but the holders on the 8 station are slightly smaller & the disc is slightly bigger.

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Sat 11 Jul , 2015 10:41 am

by andy_con

the current atc tool holder looks to be around 200mm

well according to my drawing I can get 8 tools in

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Sat 11 Jul , 2015 14:15 pm

by andy_con

anyone got any tips on how to remove the ally disc that holds all the tools, cant seem to work it out??

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Sat 11 Jul , 2015 15:41 pm

by andy_con

subject to the 3 underneath, I cant find any screws or grubs anywhere. so im assuming its force that removed the tool holder?

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Mon 13 Jul , 2015 14:32 pm

by andy_con

ok with a few tips from tom I have the ATC off.

I have two questions for denford

do you know exact distance between hole centres? are there any drawings anywhere?

and same do you know have any drawings showing position of these holes in relation to centre hole?

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Tue 14 Jul , 2015 21:20 pm

by andy_con

ill just continue posting, even if there is a lack of help being offered

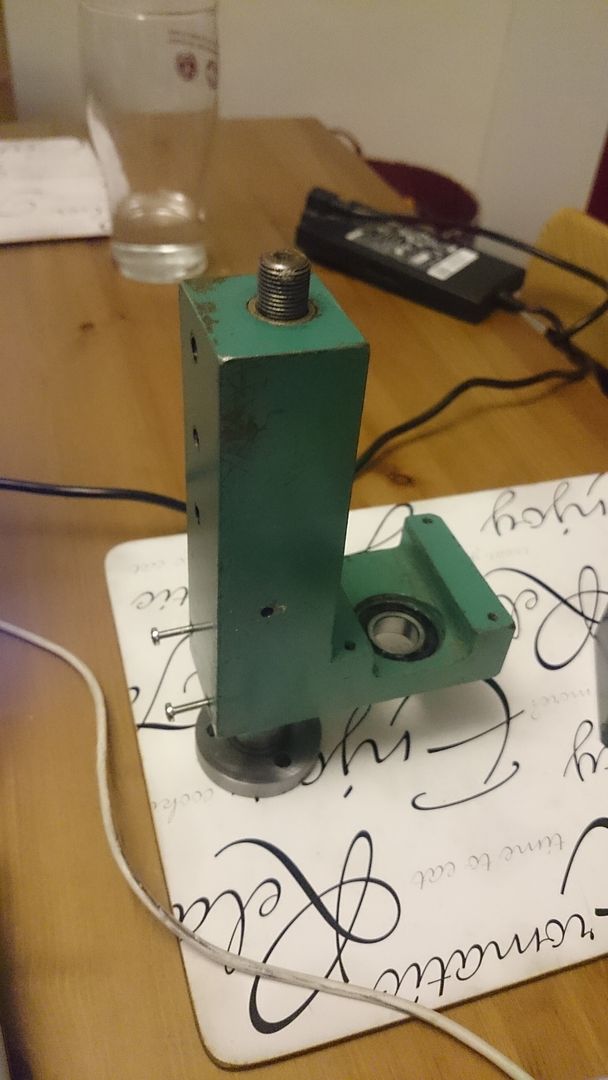

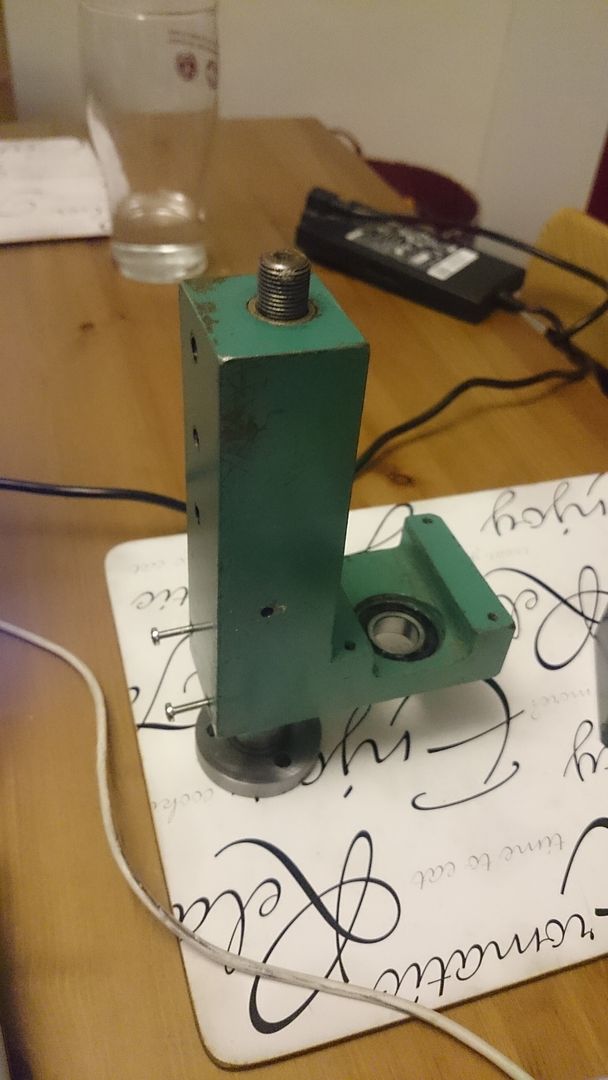

ended up taking the atc arm out that holds the tools so I could CAD it up properly.

new 8 station design with nema 23 driving it

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Wed 15 Jul , 2015 16:53 pm

by Steve

Hope these drawings help.

Have work to do as well as creating pdf's so sorry about the delay.

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Wed 15 Jul , 2015 17:32 pm

by andy_con

Steve wrote:Hope these drawings help.

Have work to do as well as creating pdf's so sorry about the delay.

they are perfect many many thanks.

out of interest did denford make two different TR3_0767 as the centre of the two bearings on mine measures 47mm?

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Wed 15 Jul , 2015 17:43 pm

by Steve

I am not sure. This is the 8 station version I think. Maybe a different part number on the 6 station one.

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Wed 15 Jul , 2015 18:08 pm

by andy_con

Steve wrote:I am not sure. This is the 8 station version I think. Maybe a different part number on the 6 station one.

fair enough thanks.

did I see in the nova section denford sell a powered drawbar setup?

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Fri 17 Jul , 2015 13:18 pm

by andy_con

im going all out now!

by flipped the part that holds the bt35 tool in you can bunch them closer together and get 10 tools on a 210mm disk

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Fri 17 Jul , 2015 14:11 pm

by Steve

Hi Denford fit a powered drawbar to the current VMC 1300.

It works much the same as the NovaMill and Triac.

I cant supply drawings for current machines but some of the parts are common and could be supplied.

It uses 44 springs in the chain and a similar power transmission to the NovaMill.

Re: 8 station ATC vs 6 station ATC - differences?

Posted: Fri 17 Jul , 2015 14:24 pm

by andy_con

Steve wrote:Hi Denford fit a powered drawbar to the current VMC 1300.

It works much the same as the NovaMill and Triac.

I cant supply drawings for current machines but some of the parts are common and could be supplied.

It uses 44 springs in the chain and a similar power transmission to the NovaMill.

ok many thanks

making mountings and things is the easy part its getting hold of a decent powered drawbar setup that's the hard bit.

may enquire about pricing at some point