im looking at the idea of changing the spindle motor on my triac, mine currently has a 4k rpm spindle. it would be nice to have a minimum of 10000rpm.

having put some thought into it, it would appear easier to leave the power draw bar as is and just changing the spindle motor. the chinese water cooled spindle are a very reasonable price, they do a 3kw at 24000rpm. im thinking 2:1 so id be getting 12k rpm which would be perfect.

has anyone done something similar?

things i need to look into further -

what belt/pully does the power draw bar use now

can i get a pully that will fit a Chinese spindle that will give me a 2:1 ratio without the need to alter the one on the power draw bar. cos that would make life very easy.

all comments welcome

Changing Spindle

Moderators: Martin, Steve, Mr Magoo

-

andy_con

- CNC Expert

- Posts: 190

- Joined: Fri 05 Oct , 2012 20:06 pm

- Hardware/Software: Triac Vmc with 6 station ATC

Starmills with ATC

Re: Changing Spindle

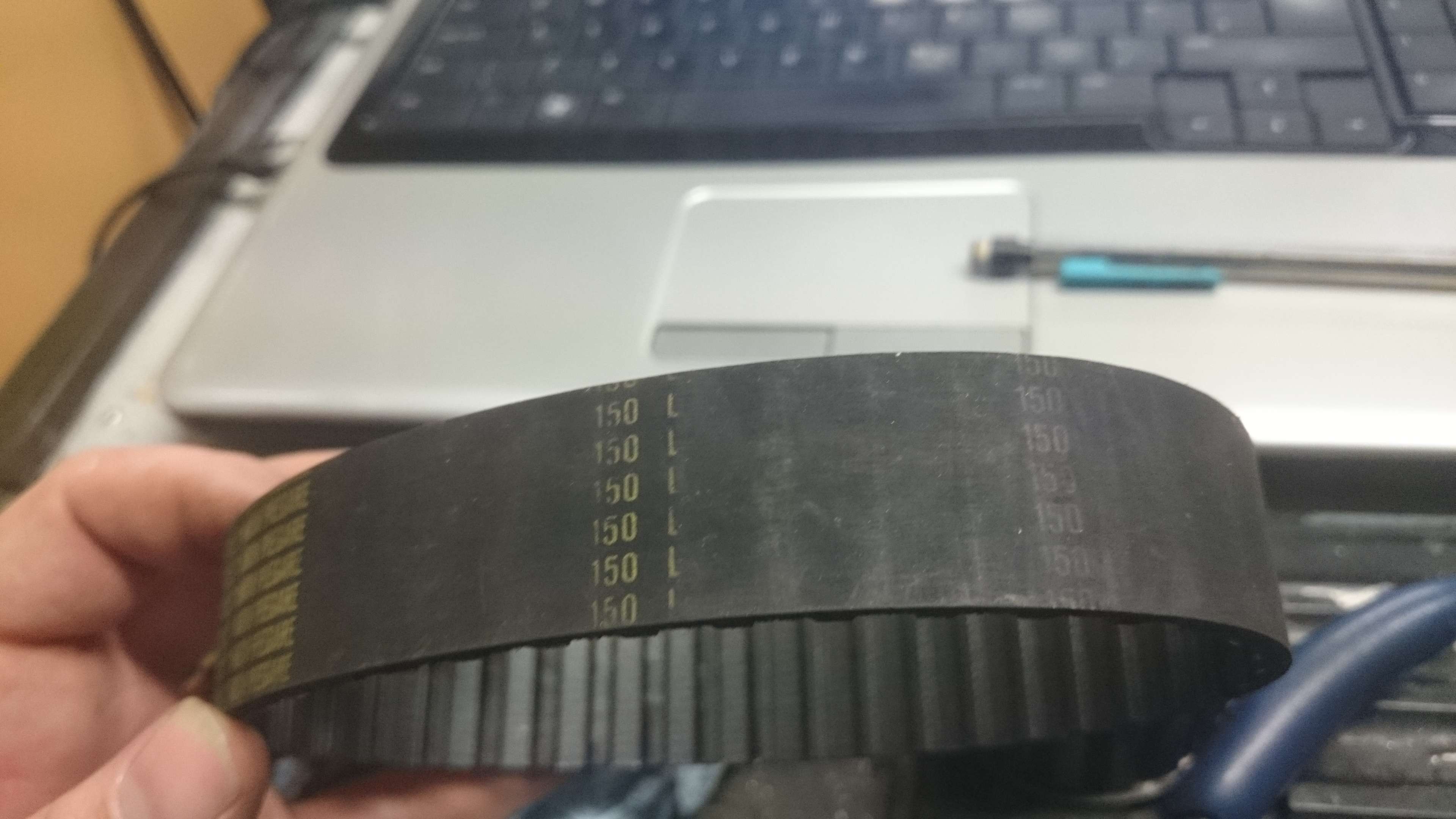

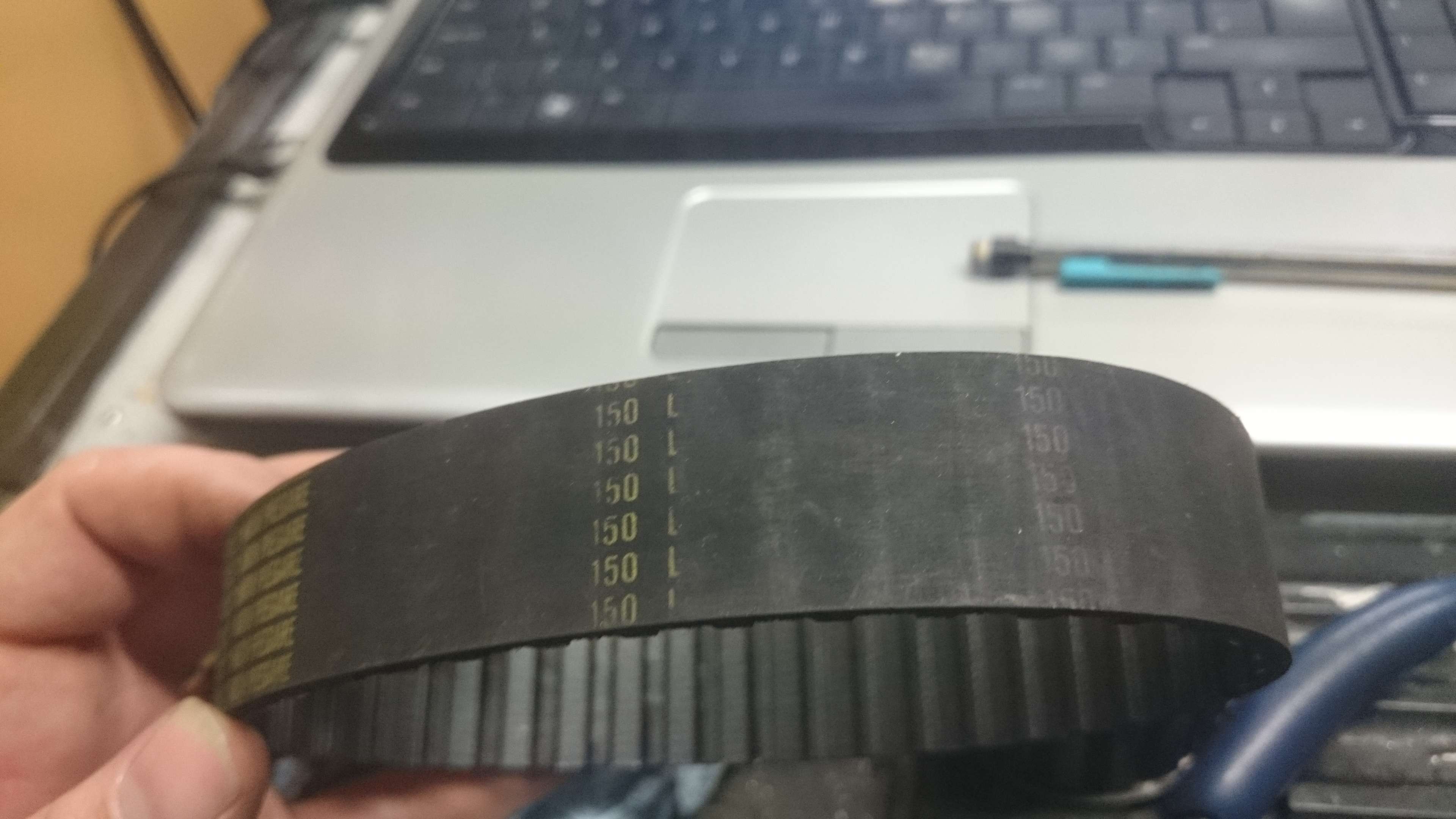

im trying to work out what exact pulley the existing motor has on it without stripping the head. i found some old photos.

can anyone tell me what pulley is on there now from the photos?

can anyone tell me what pulley is on there now from the photos?

Re: Changing Spindle

It's an L toothed belt which is a 3/8" pitch, the 18L100 would be 18 teeth L belt for 1" wide belt. 150L on the belt is 40 teeth.

https://www.bearingboys.co.uk/?catid=12 ... inch&att4=

I couldn't say whether they would do 10k RPM, you'd have to check the technical details of the pulleys, belt, and spindle bearings.

https://www.bearingboys.co.uk/?catid=12 ... inch&att4=

I couldn't say whether they would do 10k RPM, you'd have to check the technical details of the pulleys, belt, and spindle bearings.

- Lone_Ranger

- CNC Expert

- Posts: 221

- Joined: Mon 01 Oct , 2007 15:23 pm

- Contact:

Re: Changing Spindle

I think that you really need to remove the original pulley and then work out what you need dimension wise and get a pully custom made at HPC Gears, https://www.hpcgears.com/n/products/12. ... _gears.php

Won`t be cheap but you will be able to get exactly what you need.

Bearings will of course need to be changed, don`t be tempted to go for any of the Chinese hybrid Ceramic ones, I tried some on a Triac conversion where I changed the Spindle motor to a higher power Servo type motor, (Also changed the Axis motors to Mitsubishi Servos) the bearings started to fail before I had even finished testing the new system, go for the more expensive European or Japanese ones and if you can afford it go for the full Ceramic type, if you intend to use flood coolant then you need to keep it out of the bearings so top quality seals should be used early in the build.

End of the day it is up to you how far you go, 10,000rpm spindle should mean much higher rapid/cutting feed rates, I had to change all the Axis bearings and Ball Nuts as it was now capable of 20m/min rapids with the servos, the faster everything goes the higher quality of the moving parts is required

If you are going to stay with the original rapids/cutting speeds then IMHO little point in spending loads of time/effort/money on a higher speed spindle, one thing leads to another when you embroiled in stuff like this

Won`t be cheap but you will be able to get exactly what you need.

Bearings will of course need to be changed, don`t be tempted to go for any of the Chinese hybrid Ceramic ones, I tried some on a Triac conversion where I changed the Spindle motor to a higher power Servo type motor, (Also changed the Axis motors to Mitsubishi Servos) the bearings started to fail before I had even finished testing the new system, go for the more expensive European or Japanese ones and if you can afford it go for the full Ceramic type, if you intend to use flood coolant then you need to keep it out of the bearings so top quality seals should be used early in the build.

End of the day it is up to you how far you go, 10,000rpm spindle should mean much higher rapid/cutting feed rates, I had to change all the Axis bearings and Ball Nuts as it was now capable of 20m/min rapids with the servos, the faster everything goes the higher quality of the moving parts is required

If you are going to stay with the original rapids/cutting speeds then IMHO little point in spending loads of time/effort/money on a higher speed spindle, one thing leads to another when you embroiled in stuff like this