Triac power problem

Moderators: Martin, Steve, Mr Magoo

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Triac power problem

Hi,

I have joined the forum after speaking with Graham at Denford. He suggested that I try here to find out what may be wrong with my 1986 Triac mill.

For the last few weeks, when powered up, the machine datum fine, and the axis move with no problems at all. But when I tried to start the spindle, nothing happened, and a spindle fault would eventually appear. After a few tries, the spindle would start, and once it had ran, the problem didnt arise for the remainder of the day.

Today however, the same thing happened, and on the third attempt to start the spindle, the whole machine appeared to trip out, and now nothing at all powers up. There are no lights on any of the boards, and the power on light is not lit.

I have tested the glass fuses that I can see with a meter, and all appear to be ok. The power supply lead is giving 230V to the machine, as I have tested this also.

Am I missing something obvious like a fuse that I have not noticed?

Any help would be much appreciated.

Thanks

Paul

I have joined the forum after speaking with Graham at Denford. He suggested that I try here to find out what may be wrong with my 1986 Triac mill.

For the last few weeks, when powered up, the machine datum fine, and the axis move with no problems at all. But when I tried to start the spindle, nothing happened, and a spindle fault would eventually appear. After a few tries, the spindle would start, and once it had ran, the problem didnt arise for the remainder of the day.

Today however, the same thing happened, and on the third attempt to start the spindle, the whole machine appeared to trip out, and now nothing at all powers up. There are no lights on any of the boards, and the power on light is not lit.

I have tested the glass fuses that I can see with a meter, and all appear to be ok. The power supply lead is giving 230V to the machine, as I have tested this also.

Am I missing something obvious like a fuse that I have not noticed?

Any help would be much appreciated.

Thanks

Paul

- Denford Admin

- Site Admin

- Posts: 3649

- Joined: Fri 10 Feb , 2006 12:40 pm

- Hardware/Software: Go to User Control Panel > Profile

Enter as much information about your CNC hardware and software as you can - it makes it easier for everyone to know what you're talking about then. - Location: Sunny Brighouse

- Contact:

Re: Triac power problem

The logical place to start is to get the electrical drawings..the first few pages usually start with the mains power in and distribute it through fuses and circuit breakers to the transformers and PSU's etc... follow the mains by voltmeter in and see where it stops...

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Hi, thanks.

I have sorted the power issue, it was the fuse which is integral to the power supply connector.

I now still have the spindle fault.

It would try and start, and if I gave it a spin by hand on the pulley, the spindle would start. When I installed the r8 collet chuck, it didnt even try to start and tripped out the house rcd, and agin blew the preliminary fuse.

I am lucky enough to have another complete and working triac, so I swapped the spindle motors over. The fuse then blew again, so I guess there is nothing wrong with the motor?

I now have the original motor back on, with the timing belt disconnected to see if the motor would start with no resistance attached, but it still does not run.

The fuse does not blow, but i get a message saying "SPINDLE DRIVE SYSTEM ERROR".

Has anyone else seen this who may know what causes it?

I could try and swap the drive board for the spindle from the other mac hine, but I am worried that it may damage that one in doing so.

I have sorted the power issue, it was the fuse which is integral to the power supply connector.

I now still have the spindle fault.

It would try and start, and if I gave it a spin by hand on the pulley, the spindle would start. When I installed the r8 collet chuck, it didnt even try to start and tripped out the house rcd, and agin blew the preliminary fuse.

I am lucky enough to have another complete and working triac, so I swapped the spindle motors over. The fuse then blew again, so I guess there is nothing wrong with the motor?

I now have the original motor back on, with the timing belt disconnected to see if the motor would start with no resistance attached, but it still does not run.

The fuse does not blow, but i get a message saying "SPINDLE DRIVE SYSTEM ERROR".

Has anyone else seen this who may know what causes it?

I could try and swap the drive board for the spindle from the other mac hine, but I am worried that it may damage that one in doing so.

- Denford Admin

- Site Admin

- Posts: 3649

- Joined: Fri 10 Feb , 2006 12:40 pm

- Hardware/Software: Go to User Control Panel > Profile

Enter as much information about your CNC hardware and software as you can - it makes it easier for everyone to know what you're talking about then. - Location: Sunny Brighouse

- Contact:

Re: Triac power problem

Can you post a photo of the drive and possibly the error message so someone will know what drive and control it is (which may be the same as other machines)

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Ok,

I have uploaded pictures of the card which the motor connection go to. I have also taken a picture of the section on the large board at the right hand side of the machine which is labelled spindle.

I have also taken a picture of the screen showing the fault which appears after a few seconds of the spindle not responding.

Many thanks

Paul

I have uploaded pictures of the card which the motor connection go to. I have also taken a picture of the section on the large board at the right hand side of the machine which is labelled spindle.

I have also taken a picture of the screen showing the fault which appears after a few seconds of the spindle not responding.

Many thanks

Paul

- Attachments

-

- 1.jpg (58.42 KiB) Viewed 16161 times

-

- 3.jpg (64.52 KiB) Viewed 16161 times

-

- 4.jpg (87.07 KiB) Viewed 16161 times

-

- 2.jpg (32.84 KiB) Viewed 16161 times

Re: Triac power problem

Check the power & anoluge to the spindle drive.

When the spindle is requested the control looks for feeback from the spindle sensor & will clear when the requested speed has been reached. If it fails to reach the desired speed then it displays the alarm as quoted.

When the spindle is requested the control looks for feeback from the spindle sensor & will clear when the requested speed has been reached. If it fails to reach the desired speed then it displays the alarm as quoted.

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Thanks Martin,

Excuse my ignorance, but I'm guessing I am just looking for voltage between phases, and an analogue voltage of 0-10 Vdc?

Excuse my ignorance, but I'm guessing I am just looking for voltage between phases, and an analogue voltage of 0-10 Vdc?

Re: Triac power problem

L & N = 240 volts AC

A,B,C are the output to the spindle motor.

7 & 8 are the run command.

The last three will be the spindle anolgue. 0 to 10 volts DC. Not sure which terminals though.

A,B,C are the output to the spindle motor.

7 & 8 are the run command.

The last three will be the spindle anolgue. 0 to 10 volts DC. Not sure which terminals though.

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Thankyou, I will test tomorrow

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Ok,

I have had the multimeter out, and tested the terminals as kindly asked by Martin.

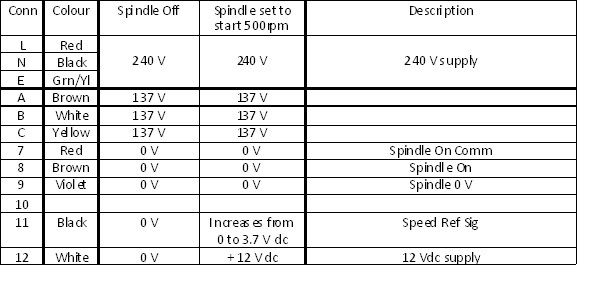

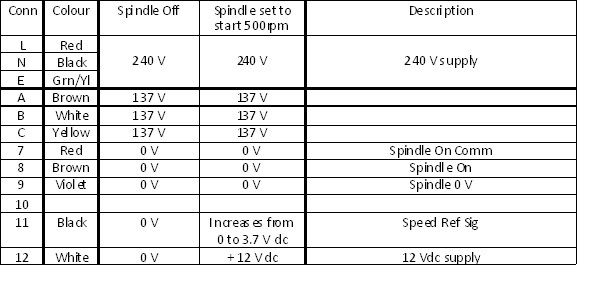

My findings are shown in the table below.

The voltages to the Spindle motor windings stay at 137 Vac regardless of whether the spindle is off or on, and I get no voltage between terminals 7 and 8 which is the Spindle ON (or run) command, so I am assuming that the Spindle On command is missing, and this is my problem??

The 0-10Vdc spindle analogue ramps from 0 - 3.7Vdc before the machine gives the Spindle drive error fault. I assume that this is working fine?

The 12Vdc is present between 9 and 12 when the spindle is told to run.

Any ideas as to why the spindle run command would be missing (assuming that I have tested for it correctly by measuring for dc voltage across terminals 7 and ?

?

Really appreciate the help guys

Paul

I have had the multimeter out, and tested the terminals as kindly asked by Martin.

My findings are shown in the table below.

The voltages to the Spindle motor windings stay at 137 Vac regardless of whether the spindle is off or on, and I get no voltage between terminals 7 and 8 which is the Spindle ON (or run) command, so I am assuming that the Spindle On command is missing, and this is my problem??

The 0-10Vdc spindle analogue ramps from 0 - 3.7Vdc before the machine gives the Spindle drive error fault. I assume that this is working fine?

The 12Vdc is present between 9 and 12 when the spindle is told to run.

Any ideas as to why the spindle run command would be missing (assuming that I have tested for it correctly by measuring for dc voltage across terminals 7 and

Really appreciate the help guys

Paul

Re: Triac power problem

Try shorting out 7 & 8 . Spindle run.

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Hi Martin,

I have shorted the two terminals with a small link wire, but it has made no difference. The machine still gives the same fault.

Here is a pic of what I have done

thankyou again for your help

Paul

I have shorted the two terminals with a small link wire, but it has made no difference. The machine still gives the same fault.

Here is a pic of what I have done

thankyou again for your help

Paul

- Attachments

-

- IMG-20111111-00039 (Small).jpg (34.37 KiB) Viewed 16137 times

- Denford Admin

- Site Admin

- Posts: 3649

- Joined: Fri 10 Feb , 2006 12:40 pm

- Hardware/Software: Go to User Control Panel > Profile

Enter as much information about your CNC hardware and software as you can - it makes it easier for everyone to know what you're talking about then. - Location: Sunny Brighouse

- Contact:

Re: Triac power problem

I would expect there to be 12V on one of the RUN pins - probably spindle run common.

Test both in relation to 0V and 12V

See if you can trace a problem with that - maybe a fuse has gone or there is some other kind of interlock on the board which won't accept the run input until it is safe / ready to run.

Test both in relation to 0V and 12V

See if you can trace a problem with that - maybe a fuse has gone or there is some other kind of interlock on the board which won't accept the run input until it is safe / ready to run.

-

angel-tech

- CNC Guru

- Posts: 525

- Joined: Tue 14 Nov , 2006 12:12 pm

- Hardware/Software: .....

4 Quatros

3 Oracs

2 Easiturn atc

12 station lathe atc

Mach 3 - Location: Quatroland

Re: Triac power problem

if this is the brown and pestell vfd, there should be a set of contacts around the back called the fanning strip which are used for run and 0-10v. and these are 8 and 9 for forward and 7 and 9 for reverse. It looks like 4 and 5 are 0-10v.

Please check first, and be careful as this inverter uses a live 0v rail so do not earth the 0-10v.

Please check first, and be careful as this inverter uses a live 0v rail so do not earth the 0-10v.

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

Hi again,

I have just been out to test the voltages on the fanning strip.

When I ask the machine to start the spindle in forward rotation, I get 12Vdc between pins 7 and 9.

In reverse rotation, I get 12Vdc between pins 8 and 9.

I tested between pins 4 and 5 for 0-10Vdc. I found that I got approximately 0.5Vdc for a couple of seconds after hitting the E.O.B key, then it disappeared completely. After a further 5 seconds or so, the fault appears on the screen.

There is a resistor between pins 5 and 6. I tested for 0-10Vdc between 4 and 6 aswell, and got the same scenario.

There is a red LED between pins 3 and 9. It illuminates as soon as I ask the spindle to start, and stays lit until the fault appears on the screen.

Kind Regards

Paul

I have just been out to test the voltages on the fanning strip.

When I ask the machine to start the spindle in forward rotation, I get 12Vdc between pins 7 and 9.

In reverse rotation, I get 12Vdc between pins 8 and 9.

I tested between pins 4 and 5 for 0-10Vdc. I found that I got approximately 0.5Vdc for a couple of seconds after hitting the E.O.B key, then it disappeared completely. After a further 5 seconds or so, the fault appears on the screen.

There is a resistor between pins 5 and 6. I tested for 0-10Vdc between 4 and 6 aswell, and got the same scenario.

There is a red LED between pins 3 and 9. It illuminates as soon as I ask the spindle to start, and stays lit until the fault appears on the screen.

Kind Regards

Paul

- Denford Admin

- Site Admin

- Posts: 3649

- Joined: Fri 10 Feb , 2006 12:40 pm

- Hardware/Software: Go to User Control Panel > Profile

Enter as much information about your CNC hardware and software as you can - it makes it easier for everyone to know what you're talking about then. - Location: Sunny Brighouse

- Contact:

Re: Triac power problem

It certainly sounds like the Brown and Pestell.

The manual here includes lots of fault finding info:

viewtopic.php?t=1243&highlight=pestell

The manual here includes lots of fault finding info:

viewtopic.php?t=1243&highlight=pestell

-

angel-tech

- CNC Guru

- Posts: 525

- Joined: Tue 14 Nov , 2006 12:12 pm

- Hardware/Software: .....

4 Quatros

3 Oracs

2 Easiturn atc

12 station lathe atc

Mach 3 - Location: Quatroland

Re: Triac power problem

4 must be one of the 0-10 connections but from the diagram i have here i'm not sure which of 5 or 6 is the other. Which ones are connected.?

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

5 only has one end of a resistor connected to it. 6 has the other end, and also two black wires.

Regards

Paul

Regards

Paul

-

angel-tech

- CNC Guru

- Posts: 525

- Joined: Tue 14 Nov , 2006 12:12 pm

- Hardware/Software: .....

4 Quatros

3 Oracs

2 Easiturn atc

12 station lathe atc

Mach 3 - Location: Quatroland

Re: Triac power problem

so 5 has no wires connected and 4 and 6 have wires.?

-

PDodds

- CNC Apprentice

- Posts: 35

- Joined: Wed 09 Nov , 2011 17:17 pm

- Hardware/Software: Triac '87 converted to mach3

Orac '85 converted to mach3

Re: Triac power problem

yes, that is correct.

thanks

Paul

thanks

Paul