first off i bought the lathe on ebay, and it was 250 miles away. you hear all the horror stories about buying unseen machines, this is turning into one of them

here it is arriving on the back of a transit dropside

we had split the lathe and cabinet to make it easier to handle, very glad i did! would of been a hairy drive home in the horiontal rain with a top heavy machine in the back

cabinet + old man

and the lathe

not the best way to lift it with the stap round the leadscrew like that but was the only way, did pack it out with wood to stop any deflection though ad it still turns

then it was time to address the problems...

1. guy said the screwcutting box was stiff through lack of use, had a look before i handed the cash over. couldnt see any missing teeth so fine

2. no coolant pump, switch or contactor. fine must of been a budget model or something

3. tachometer not working

4. lots of backlash in the topslide

well someones been telling fibs

when i got the lathe back i looked a little deeper.....

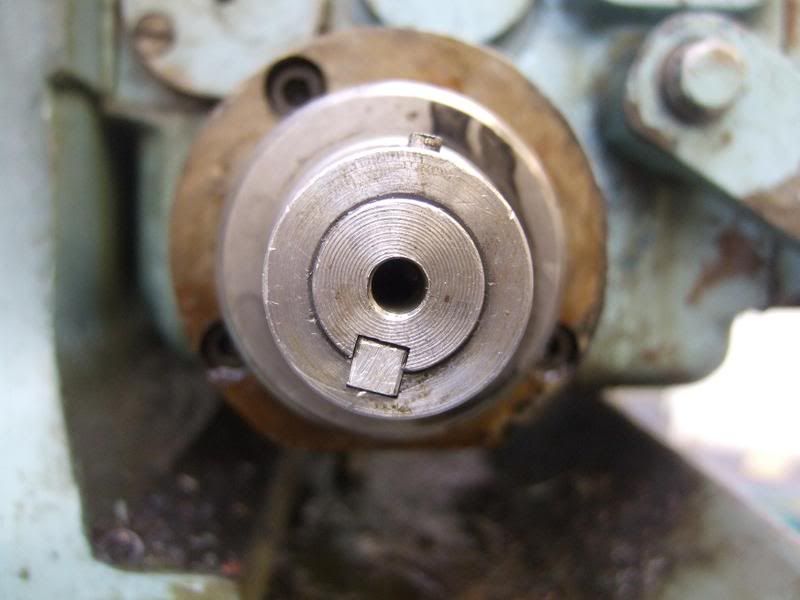

can you tell what it is yet?

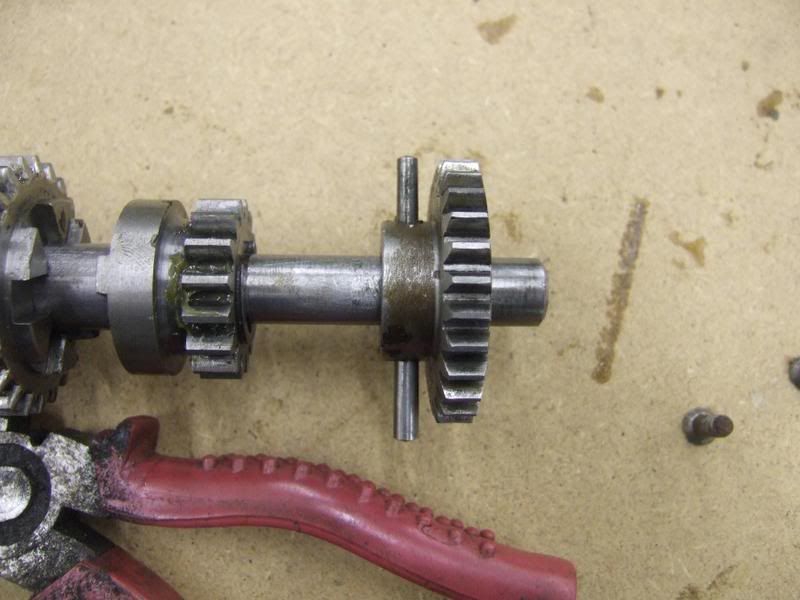

the key the lead screw/power feed selector gear slides along was bent like a bananna! and this key also locks the gear that transfers power to the shaft so the gear was spinning free on the shaft

theory is that someone has had the power feed going, then engaged the clasp nuts and locked the saddle = crunch! although there should be an aluminium shear key to prevent such disasters

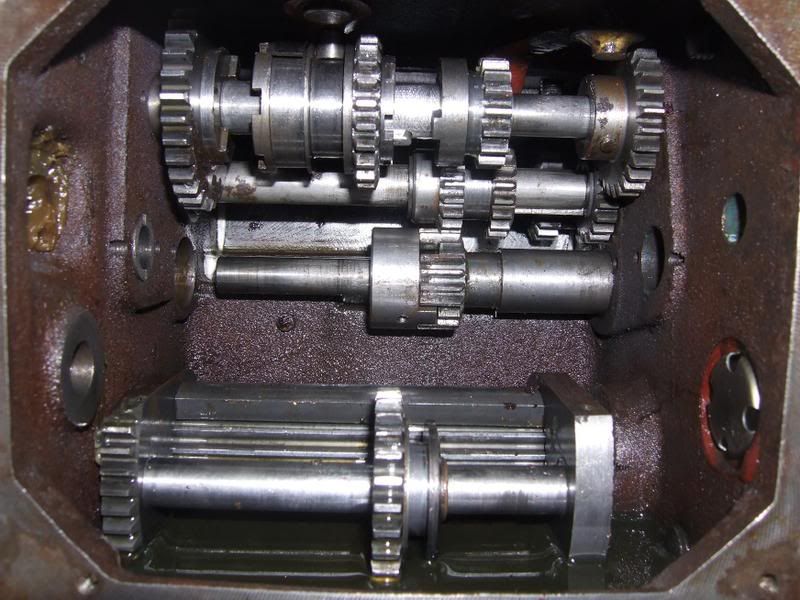

so im left with an empty gearbox

and a couple of bits

i hammered and filed the key flat again but it had damaged itself and the shaft quite a bit, looks like the first job for the lathe is to turn itself a new shaft

back in the gearbox

can just see the now straight key and the gear that slides along it, as well as the power transfer gear thats also held by the key

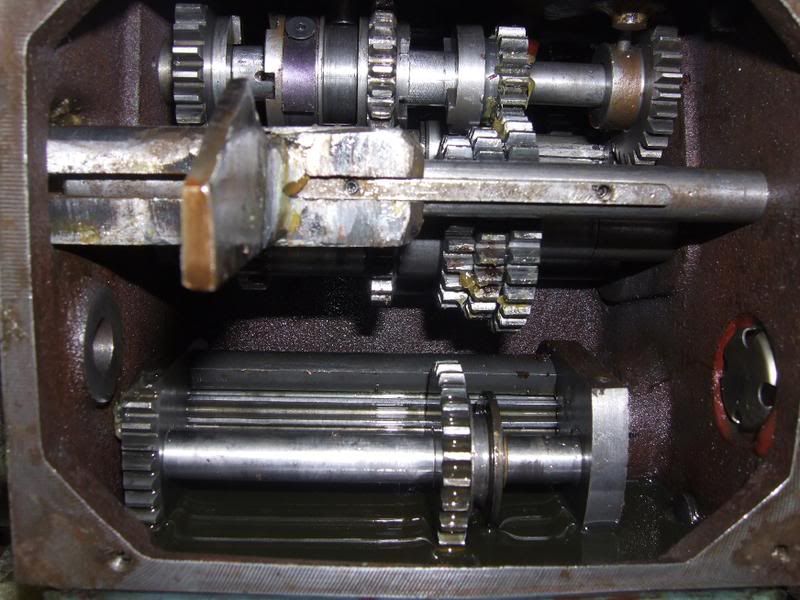

another problem was the other selector mechanism was a bit siezed, so striped it

can just see the damage by the detent holes, a quick file and a polish the thing was sliding again

the old taper pin took a beating coming out so had to fit a new one, by sheer jammy luck i had bought a box of 3/16'' taper pins the month before

needs trimming....

shaft back in and the selectors all selecting

more gears

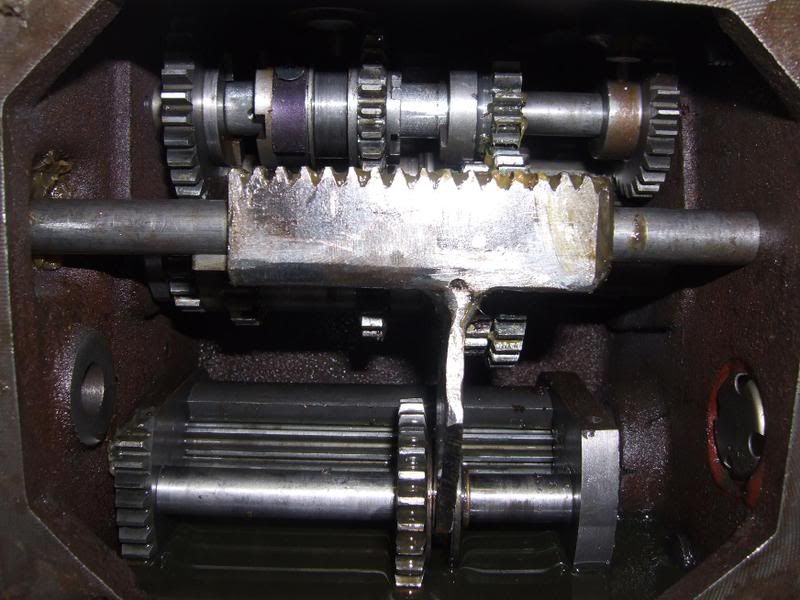

a point to note if anyones going to stirp a viceroy 280 gearbox (never know) imperial grub screws! sneaky beggers

another slidey selector

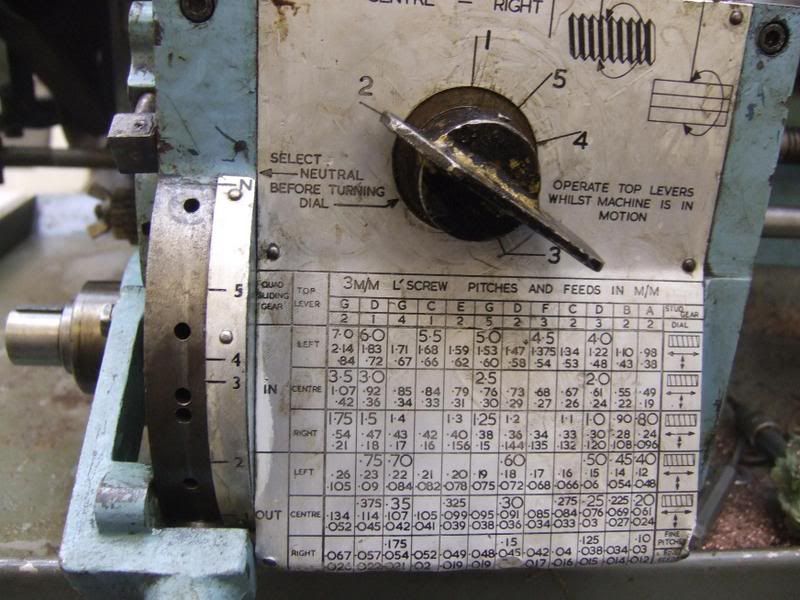

well got the gearbox sorted! thought i was going mad but turns out the dial is wrong! someones been at this lathe big style

here is what i mean

now for this box to work the numbers on the lever and the dial need to match, but as can be seen the dial is at 2 and the lever at 1. this is in fact gear 1, either someone has replaced it with a dial from another machine with the pin in the wrong place or its one of the dials from the top of the gearbox.

also found the aluminium shear key

very much un damaged and definatly still aluminium, it lives behind the gears atached to the gearbox shaft. spent the rest of the day rearanging everything and shfting the lathe to its final resting position

very long first post but its about 2 weeks work in one go

also everyone seems to have uploaded ther pics to the denford server, is this preferable or is it ok to just insert the pics as i have done? saves server space