Have been using the UP printer for a few weeks now and have noticed an issue that I hope someone can help with, or may have come across themselves?

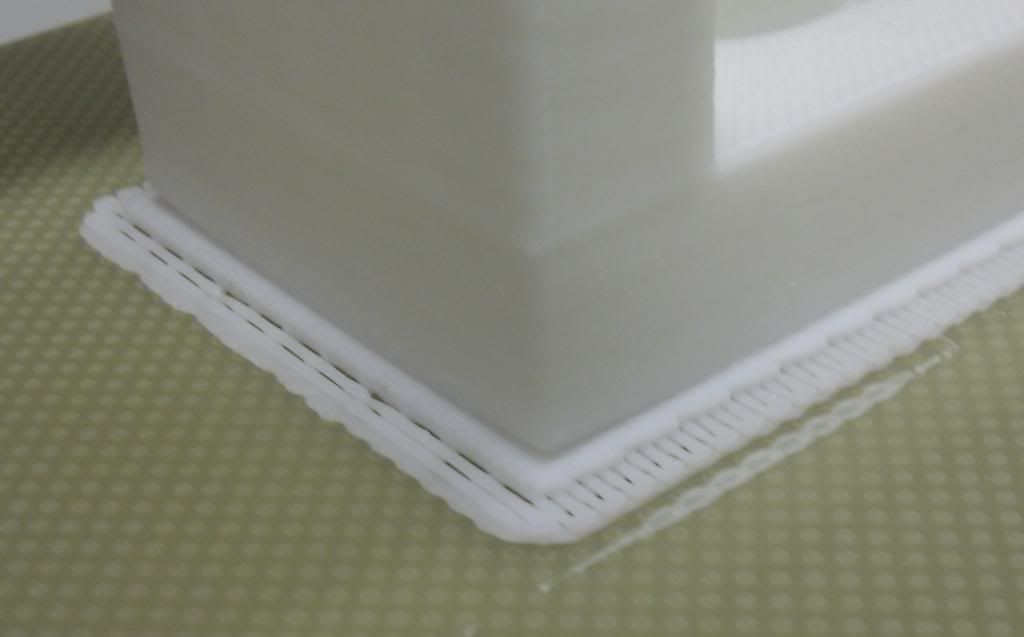

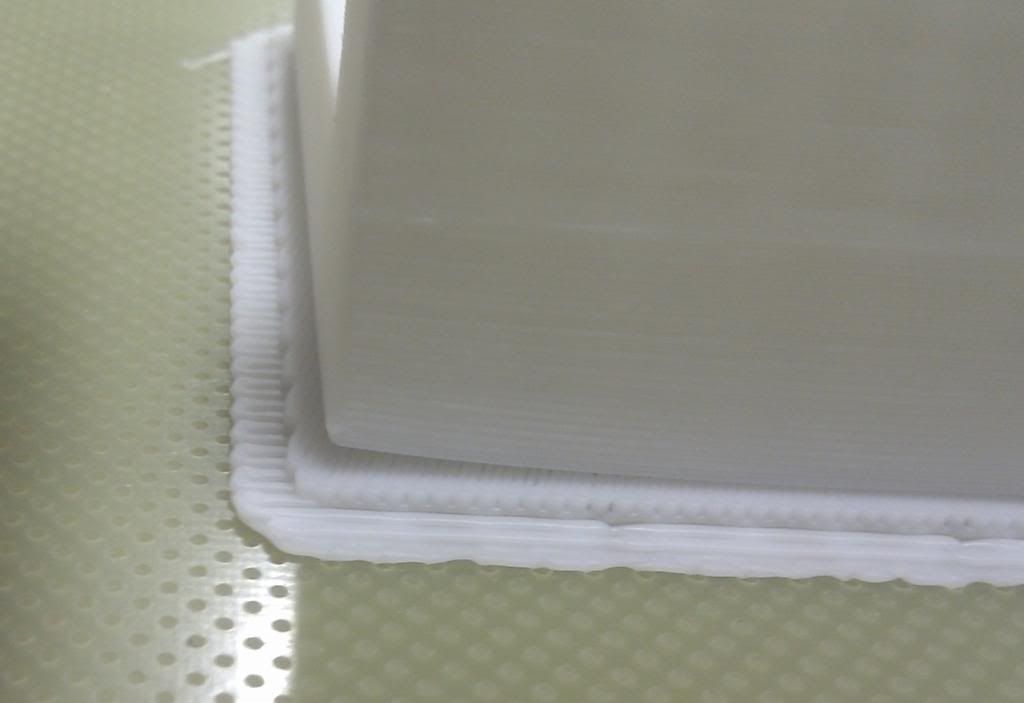

Basically when printing some objects I am getting ‘shrinkage’ at one or more of the bottom corners of the component. I have attached a couple of photos of this. The actual finished component is pulling away from the raft it is sitting on. The raft itself is fine in the sense that it isn’t coming away from the platform.

Is it something to do with un-even cooling of the plastic? Or is the component not getting a strong enough bond to the raft?

It doesn’t seem to be a particular point on the platform that this happens. I’m using default settings with either Loose or Hollow Fill.

Any advice?

Thanks,

Guy